In this article:

Class 1 / Division 2 and ATEX Zone 2 Explained

Assured Systems sell a wide range of industrial computing products certified for Class 1 / Division 2 and ATEX Zone 2 areas.

Explosions can cause significant damage along with severe injury or worse loss of life. To prevent explosions from happening in harsh environments whereby flammable gases or combustible dusts are present directives and guidelines are put in place to protect both the public, workforce, and environment.

Both the USA and the European Union have their certifications and guidelines to control the risks from dangerous substances igniting. This article defines explosive atmospheres, summarises the regulations in both the USA and the European Union, and demonstrates Industrial Computers, Panel PCs and Data Acquisition hardware certified for installation in explosive atmospheres.

What is an explosive atmosphere?

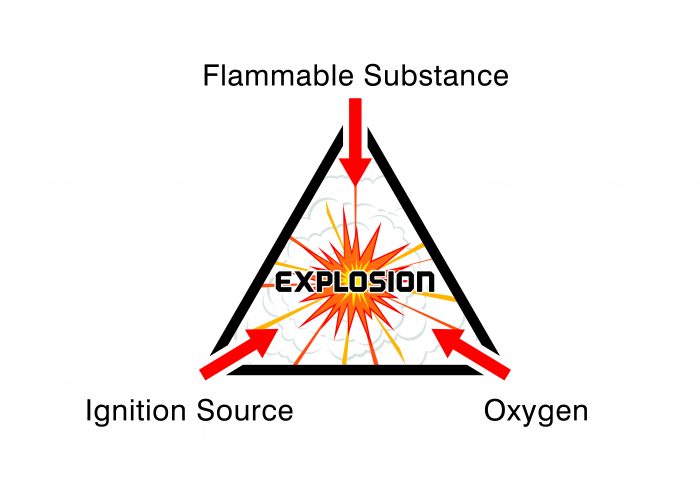

According to The Dangerous Substances and Explosive Regulations, commonly known as DSEAR, an explosive atmosphere is defined by a mixture of dangerous substances within the air under atmospheric conditions. The atmospheric conditions are most commonly referred to their ambient temperatures and pressures, for example, a temperature of –20°C to 40°C and pressure of 0.8 to 1.1 bar. Three components are necessary for an explosion to occur:

|

Flammable Substance

This needs to be present in a relatively high quantity to produce an explosive mixture (e.g. gas, vapours, mists and dusts). Oxygen Oxygen is required in high quantities and in combination with the flammable substance to produce an explosive atmosphere. An Ignition Source A spark or high heat must also be present. |

Where can an explosive atmosphere be found?

An explosive atmosphere can be found in both public spaces and within the workplace across many different types of industries. An example of an explosive atmosphere whereby flammable gases or vapours are present would be a fuelling station. An example of an explosive atmosphere whereby organic dusts such as grain flour or wood would be a timber sawmill.

Understanding Explosive Atmospheres

Protecting the public, workforce and environment from explosive atmospheres is paramount but not a universal standard. Both the USA and the European Union have similar standards but are defined slightly different to each other.

In the US, NEC (National Electric Code) is followed, which puts HAZLOC (Hazardous Locations) into classes, divisions (and groups for the type of materials present) and for Europe, IEC (International Electrotechnical Commission) classifies HAZLOC by zones. Products such as a panel PC will then be certified to be safe in these areas before they can be applied.

In North America products are listed by UL (Underwriters Laboratories, a global safety consulting and certification company based in the US and 45 other countries) under what level of Class and Division the product is suitable for, whilst ATEX uses certified bodies to classify products for use in the EU.

Outside of the European Union, regulations apply under the IEC Ex (International Electrotechnical Commission – System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres). IEC Ex is a voluntary system which provides an internationally accepted means of proving compliance with IEC standards. IEC standards are used in many national approval schemes and as such, IEC Ex certification can be used to support national compliance, negating the need in most cases for additional testing.

UL Classes aND divisions |

|

UL Classes for Ignitable Substance

| Class 1 | Flamable gas, vapours, and liquids. |

| Class 2 | Combustible dusts. |

| Class 3 | Ignitable fibers and flyings. |

UL Divisions for Operating Conditions

Divisions go further in classifying how often the flammable or explosive substances are likely to be present under normal operating conditions.

| Division 1 | Flammable substances are continually present or are likely to exist under normal operating conditions. |

| Division 2 | Flammable substances are not likely to exist under normal operating conditions. |

ATEX Directives and Certifications |

|

The abbreviation ATEX is derived from the French words, ATmosphères EXplosibles and represents 2 European directives stipulated for controlling explosive atmospheres:

1) Directive 99/92/EC (also known as ‘ATEX 137’ or the ‘ATEX Workplace Directive’) on minimum requirements for improving the health and safety protection of workers potentially at risk from explosive atmospheres.

2) Directive 94/9/EC (also known as ‘ATEX 95’ or ‘the ATEX Equipment Directive’) on the approximation of the laws of Members States concerning equipment and protective systems intended for use in potentially explosive atmospheres.

ATEX classifications are in zones, derived from the US ‘HAZLOC’ standard. They combine the ‘Class’ area classification and the ‘Division’ likelihood of explosive substance presence. It subdivides powders and dust from gases and vapors.

ATEX directives and certifications for gasses, vapours and mists

| ATEX Zone 0 | A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapor or mist is present continuously or for long periods or frequently. |

| ATEX Zone 1 | A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapor or mist is likely to occur in normal operation occasionally. |

| ATEX Zone 2 | A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapor or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only. |

ATEX directives and certifications for combustible dusts

| ATEX Zone 20 | A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, or for long periods or frequently. |

| ATEX Zone 21 | A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally. |

| ATEX Zone 22 | A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only. |

Comparing UL Classes and Divisions with ATEX Directives

| Class 1 / Division 1 :: Zone 0 & Zone 1 |

Where ignitable concentrations of flammable gases, vapours, or liquids:

|

| Class 1 / Division 2 :: Zone 2 |

Where ignitable concentrations of flammable gases, vapours, or liquids:

|

To put this into perspective here is an image of a fuelling station outlining the different zonings applied:

Class 1 / Division 1 :: ATEX Zone 0 – Red Zone

Class 1 / Division 1 :: ATEX Zone 1 – Orange Zone

Class 1 / Division 2 :: ATEX Zone 2 – Yellow Zone

Industrial Computing for Class 1 / Division 2 and ATEX Zone 2

Where embedded electrical products are concerned, the requirement for harsh environment industries such as oil and gas will usually be certification to Class 1 / Division 2 and/or ATEX Zone 2.

Assured Systems offer a comprehensive range of Class 1 / Division 2 and/or ATEX Zone 2 qualified products including panel PCs, embedded computers, data modules and screens. View our ranges below – If there is something you need which is not listed, please contact us and our sales technicians will help to find you a solution.

View Our Class 1 / Division 2 and ATEX Zone 2 Approved Products

We can make your (Class 1/Division 2, ATEX Zone 2) project idea into a turnkey solution reality!

We offer a comprehensive solution service which includes extrusion design, manufacture, software programming and project management support. We have experience in large turnkey solutions for Class 1 / Division 2 and ATEX Zone 2 environment projects, be sure to give us a call +44 (0) 1785 879 050 UK or +1 864 421 6991 US to discuss yours.