In this article:

PCAP Touch Screen Computers

Assured Systems are a system integrator for a wide range of PCAP touch screen computers with anti-glare, anti-reflection and anti-fingerprint coatings. We have both commercial and industrial solutions available and can help find the right solution for you.

Assured Systems is a professional and experienced solution provider for a wide range of PCAP Touch Screen Computers with advanced display technologies to fulfil both commercial and industrial applications. Based on both display and embedded system core technologies, Assured Systems provide a customised value-added solution to our customers to meet their critical demand and environment.

PCAP Touch Replacing Resistive Touch Technology

Most touch screens today utilise two touch technologies, projected capacitive (PCAP) and resistive touch, with PCAP touch technology being the modern user interface.

Resistive touch screens were launched about 20 years ago with a lower cost-benefit and a pressure-sensitive surface to react with various objects such as your finger, glove, pencil or specialist tools. Resistive touch technology remains the popular choice for factory automation. Some drawbacks for resistive touch technology include the need for calibration from time to time, a driver is needed for new installations, and the surface of the resistive touch display has a limited lifetime. The resistive touch technology also suffers from reduced light transmittance in comparison with PCAP, therefore, decreases the sought-after high brightness of the underlying TFT-LCD.

The advantage of PCAP touch technology is a direct contact between the finger and touch technology is not needed for operation. A glass plate can be mounted as an outer transparent protective layer without interfering with the touch functionality. The choice of material and thickness of the plate may even protect the system from vandalism in public places. It’s worth mentioning that the operating life of the touch screen generally is well over the operating life of the display. Under a Windows operating system, users can easily change the touch mode in just one click without the need to reboot for the change to take place. This increases the working efficiency for customers who need to install or utilise their panel computers in different places.

Anti-Glare, Anti-Reflection and Anti-Fingerprint Coatings

Assured Systems provide 3 different surface coatings for PCAP touch screen computers; Anti-Reflection, Anti-Glare and Anti-Fingerprint. These surface coatings can be utilised in both indoor and outdoor environments by enhancing the optical performance of displays.

Anti-Glare Coating Treatment

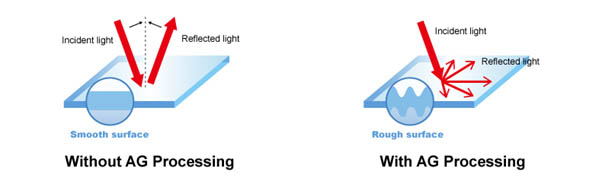

There are 2 different kinds of treatment for touch displays with an Anti-Glare coating.

A chemical-based surface treatment, otherwise known as a chemical AG process, is applied directly to the glass display surface to form micro asperities and give the glass an anti-glare effect under the likes of sunlight. It does not generate any of the minute flaws or micro-cracks that are characteristic of mechanical AG processes and therefore maintains the high surface strength of the glass.

The other way for AG treatment is manufactured by a controlled acid etching process yielding uniform diffused surfaces for anti-glare. Varying levels of diffusion specified as gloss yield different levels of reduced glare. A lower gloss reading denotes a more diffuse panel. The haze ratio of AG glass used on OGS touch screen products cannot be too high, because high levels of haze would affect LCM transmittance. See below figure to have more understanding of specification categories for anti-glare glass.

| AG Glass | Touch Monitor |

| Haze (%) | 3.0 ~ 5.0 ± 0.5 |

| Gloss Unit (GU) | 80 ~ 90 |

| Ra (Roughness) | < 0.4 |

| Transmittance (%) | 85 ~ 90 |

Anti-Reflection Coating Treatment

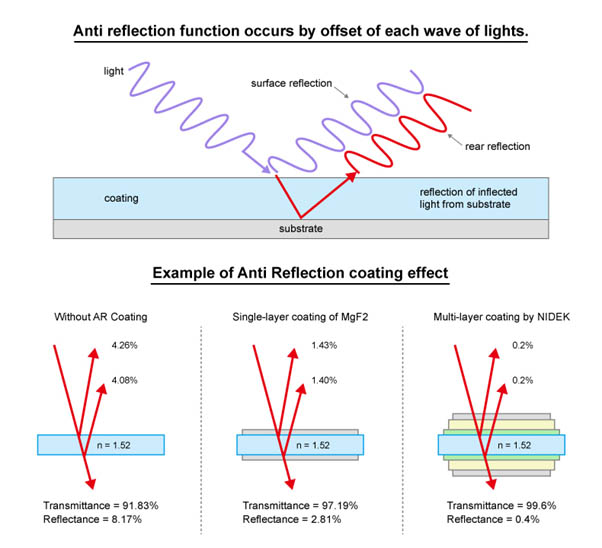

An Anti-Reflection (AR) coating is a type of optical coating applied to the surface and other optical elements to reduce reflection by the vacuum evaporation process. In typical imaging systems, this improved efficiency since less light is lost due to reflection. In a complex system such as telescopes and microscopes, the reduction in reflections also improves the contrast of the image by elimination of stray light.

AR produced destructive interference in the beams reflected from the interfaces and constructive interference in the corresponding transmitted beams, which increases the transmittance of glass or transparent substrates, the transmittance of glass is approximately 91%, with single-sided coating the transmittance can increase to 94~95%, if with double-sided coating it can increase transmittance up to 98~99%.

Anti-Fingerprint Coating Treatment

The Anti-Fingerprint coating constructions of the advantages of the preferred embodiments like the user are prevented from being imprinted on the surface, and it remains clean and aesthetically pleasing. AFP coating makes it possible to wipe up smudge on the surface very quickly and also has a tremendous hydrophobic performance and protects AR layers and reduced friction and low surface energy and improves scratch resistance. The hydrophobic performance is evaluated each lot by measuring the contact angle. The AF effect is realized by applying a nano-coating to reduce the optical contrast of fingerprints.

The AFP effect means that fingerprint on the surface cannot be seen at all by the naked eye, or only very slightly. Although the fingerprint is on the surface, it is essentially “invisible.” The colour to be coated under visible and infrared light is transparent. The coating is with characteristics like low coefficient of friction, contact angle >100 degrees. It utilizes a vacuum coating process which is also thinner and more even than spread coating.

Anti-Vandal Surface Protective Coatings

Glass is often considered the weakest point of projective capacitive touch panel computers. It can be break under several situations, including extreme weather, vandalism, and occasional accidents. To minimize the damage from a break-in or other disasters, a protective film can be installed to make the cover lens harder to break. Even when attempting to shatter the glass panel, the security film will hold the glass in place, reducing the overall impact of the breakage. This is an advantage for the food industry where trace elements cannot be subdued into the product, or the batch would have to be discarded.

Anti-Vandal display protective films work by protecting the glass substrate from damage and can be easily removed and replaced by a new film. This provides a quick on a cost-effective solution for those required to maintain public and private spaces from the damage and visual distortion caused by graffiti and reckless vandalism.

Anti-UV protective films are applied for outdoor Panel PCs which are operating in both outdoor and semi-outdoor applications. Even though that is indirect sunlight for the touch surface, there are still ultraviolet light that can damage the structure of touch and cause OCA film yellowing and aging issues. Anti-UV films also reject up to 97% of infrared light coming from sunlight and insulation up to 60% of the heat keep touch surface and system away from heat issues.

Discuss Your PCAP Touch Screen Computer Application with Assured Systems

Assured System’s sales team in both the UK & USA have years of experience in applications requiring the installation of PCAP Touch Screen Computers. We thoroughly understand our products, our customers, and the applications in which our systems are being deployed. You can rely on our expertise to ensure you receive the right guidance resulting in a precise fit for your requirements every time, saving you time and effort, and ultimately money. If you have an application you would like to discuss, please call +44 1785 87 90 50 (EMEA) or +1 864 421 6991 (USA) or use the contact form to send us your requirements.