Dans cet article:

- Introduction

- Calcul haute performance avec le processeur Intel® Alder Lake N97

- Interface E/S complète pour la communication industrielle

- Applications réelles du Neousys Nuvo-2822

- Conclusion

Introduction

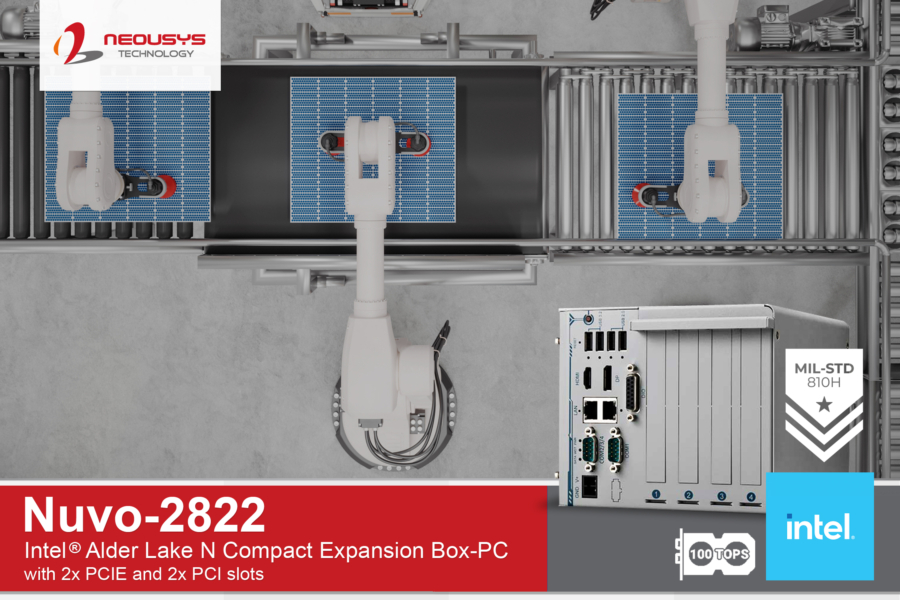

Dans le monde de l'automatisation industrielle et de la fabrication intelligente, des solutions informatiques compactes et robustes sont essentielles pour rationaliser les opérations, réduire les temps d'arrêt et améliorer la productivité. Le Neousys Nuvo-2822 est un ordinateur industriel puissant et ultra-compact conçu pour relever ces défis. Équipé du processeur Intel® Alder Lake N97, cette machine petite mais puissante offre un haut niveau de puissance informatique, de polyvalence et de fiabilité, ce qui en fait une solution parfaite pour les applications industrielles qui exigent robustesse et flexibilité.

Cet article approfondit les caractéristiques, les spécifications et les applications réelles du Nuvo-2822, mettant en évidence son potentiel à révolutionner les industries telles que la fabrication, la vision industrielle, l'automatisation et l'acquisition de données.

Calcul haute performance avec le processeur Intel® Alder Lake N97

Le Neousys Nuvo-2822 est équipé du processeur Intel® Alder Lake N97, qui fait partie de la série Alder Lake-N d'Intel. Ce processeur est connu pour son architecture quadricœur, quatre threads, délivrant des vitesses d'horloge de 2,0 GHz, avec la possibilité de booster jusqu'à 3,6 GHz en cas de besoin. Cela garantit que le système peut gérer des charges de travail intensives sans compromettre les performances, tout en maintenant la consommation d'énergie à un modeste TDP de 12 W.

Comparé à ses prédécesseurs tels que l'Intel Atom, le N97 Alder Lake offre une amélioration notable de la vitesse de traitement et de l'efficacité. Ce saut de performance rend le Nuvo-2822 hautement capable d'exécuter des applications qui nécessitent un traitement rapide des données et des calculs en temps réel. Avec Intel® UHD Graphics intégré dans le système, les utilisateurs bénéficient d'une performance graphique améliorée, ce qui est particulièrement bénéfique pour les tâches de vision industrielle et d'inspection visuelle dans les environnements industriels.

Des options d'extension flexibles pour une gamme d'applications industrielles

L'une des principales caractéristiques du Nuvo-2822 est sa capacité d'extension polyvalente, qui comprend deux emplacements PCIe et deux emplacements PCI. Ces emplacements d'extension sont essentiels pour ajouter des cartes personnalisées au système, ce qui permet d'adapter le Nuvo-2822 à un large éventail d'applications.

Exemples de cartes d'extension et de leur utilisation :

- Cartes d'acquisition : Utilisées dans les systèmes de vision industrielle, les cartes d'acquisition capturent les images des caméras industrielles pour les traiter et les analyser. Cette fonction est cruciale dans des applications telles que le contrôle de la qualité dans l'industrie manufacturière, où des caméras à grande vitesse surveillent les lignes de production à la recherche de défauts.

- Cartes de contrôle de mouvement : Utilisées dans les systèmes robotiques et les machines automatisées, les cartes de contrôle de mouvement permettent un contrôle précis des moteurs, des actionneurs et des servomoteurs, garantissant un fonctionnement sans heurts dans des tâches telles que le soudage de précision, la découpe et l'emballage.

- Cartes d'acquisition de données : Ces cartes permettent au Nuvo-2822 de collecter en temps réel des données provenant de capteurs et d'appareils. Dans des secteurs tels que le pétrole et le gaz ou la surveillance de l'environnement, les cartes d'acquisition de données collectent des informations critiques à partir de capteurs de température, de pression et de débit.

- Cartes d'extension de port COM : Elles permettent d'augmenter la capacité de communication série, ce qui est essentiel pour connecter les anciens appareils industriels qui dépendent de la communication série RS-232/422/485.

En prenant en charge ces cartes d'extension polyvalentes, le Nuvo-2822 s'adapte à diverses applications industrielles, de la robotique et de l'automatisation à l'acquisition de données et à la gestion des capteurs.

Conception robuste conçue pour les environnements difficiles

Les environnements industriels peuvent être difficiles, avec des niveaux élevés de vibrations, de chocs, de poussière et de températures extrêmes. Le Nuvo-2822 est conçu pour résister à ces conditions, garantissant ainsi sa fiabilité dans les environnements les plus exigeants. Il a passé les tests de choc et de vibration MIL-STD-810H, qui sont des normes militaires certifiant la durabilité du système.

Des caractéristiques clés qui renforcent la robustesse :

- Large plage de températures de fonctionnement : Le Nuvo-2822 peut fonctionner à des températures allant de -10°C à 70°C lorsqu'il est équipé du kit de ventilateur en option. Sans le kit de ventilateur, il peut encore supporter des températures allant de -10°C à 60°C. Cela garantit que le système fonctionne de manière fiable, même dans des environnements extérieurs ou dans des usines où les températures fluctuent.

- Ports USB et LAN à vis : Dans les environnements industriels, les connexions desserrées peuvent entraîner des temps d'arrêt coûteux. Les mécanismes de verrouillage à vis des ports USB et Ethernet du Nuvo-2822 garantissent des connexions sûres et empêchent toute déconnexion accidentelle en cours de fonctionnement.

- Conception sans ventilateur : Pour les applications nécessitant un environnement sans poussière, le Nuvo-2822 peut être configuré avec un système de refroidissement sans ventilateur en option. Ceci est particulièrement important dans les environnements agroalimentaires ou pharmaceutiques où la contamination doit être minimisée.

Grâce à ces caractéristiques de conception robuste, le Nuvo-2822 est parfaitement adapté aux déploiements en extérieur, aux usines, aux chantiers de construction et même aux applications militaires où une informatique robuste est nécessaire dans des conditions extrêmes.

Efficacité énergétique avec le mode super économie d'énergie

L'un des aspects souvent négligés de l'informatique industrielle est l'efficacité énergétique. Alors que le monde évolue vers des technologies plus écologiques, la réduction de la consommation d'énergie devient une priorité, en particulier dans les usines qui fonctionnent 24 heures sur 24 et 7 jours sur 7.

Le Nuvo-2822 intègre un mode Super Power Saving, qui réduit considérablement la consommation d'énergie lorsque le système est en mode veille (S4/S5). Cette fonction est particulièrement utile dans les industries où plusieurs systèmes fonctionnent simultanément, car elle permet de réduire l'empreinte énergétique globale.

Par exemple, dans une usine intelligente, des centaines d'appareils peuvent être inactifs en dehors des heures de pointe, mais continuer à consommer de l'énergie. La fonction d'économie d'énergie du Nuvo-2822 minimise ce gaspillage d'énergie, ce qui permet de réduire les coûts d'exploitation et d'aider les entreprises à atteindre leurs objectifs en matière de développement durable.

L'un des principaux avantages du Nuvo-2822 est sa gamme complète d'interfaces d'E/S, qui permet une communication transparente entre le système et les périphériques externes. Ces interfaces sont les suivantes

- 2 ports Gigabit Ethernet : Ces ports utilisent des contrôleurs Intel I210-IT, garantissant une connectivité réseau rapide et fiable. L'un des ports Ethernet prend également en charge le Wake-on-LAN (WoL), qui permet de mettre le système sous tension à distance, améliorant ainsi les capacités de gestion à distance.

- 4x Ports COM : La communication série reste vitale dans les environnements industriels, et le Nuvo-2822 offre quatre ports COM pour la communication série RS-232/422/485. Ces ports sont essentiels pour contrôler et communiquer avec les dispositifs existants tels que les capteurs, les actionneurs et les contrôleurs.

- 2 ports USB 3.2 Gen 2 et 2 ports USB 2.0 : Dotés de mécanismes de verrouillage à vis pour des connexions sécurisées, ces ports USB sont idéaux pour connecter des caméras industrielles, des scanners et des dispositifs d'enregistrement de données.

- e/S numérique isolée à 8 canaux (DIO ) : L'E/S numérique isolée est essentielle pour le contrôle et la surveillance en temps réel des signaux numériques, car elle offre une fonctionnalité d'entrée/sortie à grande vitesse avec une protection contre le bruit électrique. Elle est particulièrement utile dans les environnements présentant des niveaux élevés d'interférences électromagnétiques, tels que les centrales électriques ou les usines de fabrication automobile.

Cette combinaison d'interfaces d'E/S permet au Nuvo-2822 d'agir comme un centre de contrôle et de surveillance de divers appareils industriels, ce qui le rend idéal pour les applications d'automatisation, d'enregistrement de données et de surveillance à distance.

Interface E/S complète pour la communication industrielle

L'un des principaux avantages du Nuvo-2822 est sa gamme complète d'interfaces d'E/S, qui permet une communication transparente entre le système et les appareils externes. Ces interfaces sont les suivantes

- 2 ports Gigabit Ethernet : Ces ports utilisent des contrôleurs Intel I210-IT, garantissant une connectivité réseau rapide et fiable. L'un des ports Ethernet prend également en charge le Wake-on-LAN (WoL), qui permet de mettre le système sous tension à distance, améliorant ainsi les capacités de gestion à distance.

- 4x Ports COM : La communication série reste vitale dans les environnements industriels, et le Nuvo-2822 offre quatre ports COM pour la communication série RS-232/422/485. Ces ports sont essentiels pour contrôler et communiquer avec les dispositifs existants tels que les capteurs, les actionneurs et les contrôleurs.

- 2 ports USB 3.2 Gen 2 et 2 ports USB 2.0 : Dotés de mécanismes de verrouillage à vis pour des connexions sécurisées, ces ports USB sont idéaux pour connecter des caméras industrielles, des scanners et des dispositifs d'enregistrement de données.

- e/S numérique isolée à 8 canaux (DIO ) : L'E/S numérique isolée est essentielle pour le contrôle et la surveillance en temps réel des signaux numériques, car elle offre une fonctionnalité d'entrée/sortie à grande vitesse avec une protection contre le bruit électrique. Elle est particulièrement utile dans les environnements présentant des niveaux élevés d'interférences électromagnétiques, tels que les centrales électriques ou les usines de fabrication automobile.

Cette combinaison d'interfaces d'E/S permet au Nuvo-2822 d'agir comme un centre de contrôle et de surveillance de divers appareils industriels, ce qui le rend idéal pour les applications d'automatisation, d'enregistrement de données et de surveillance à distance.

Applications réelles du Neousys Nuvo-2822

La polyvalence du Neousys Nuvo-2822 lui permet d'être utilisé dans un large éventail d'industries, ce qui en fait une solution idéale pour les applications d'automatisation, de vision industrielle et de contrôle industriel. Voici quelques exemples de déploiement du Nuvo-2822 dans des scénarios réels, démontrant ses avantages et ses capacités.

- Automatisation des usines intelligentes

À l'ère de l'industrie 4.0, les usines deviennent de plus en plus " intelligentes ", s'appuyant sur des appareils, des machines et des systèmes interconnectés pour optimiser les processus de production. Le Nuvo-2822, avec son processeur Intel® Alder Lake N97 haute performance et ses options d'extension robustes, joue un rôle central dans de tels environnements.

Cas d'utilisation : Ligne de production automatisée

Imaginez une usine produisant des composants électroniques sur une ligne d'assemblage entièrement automatisée. Le Nuvo-2822, équipé de cartes de contrôle de mouvement et de cartes d'acquisition de données, peut contrôler en toute transparence les machines chargées d'assembler les composants.

Les canaux DIO isolés du système permettent de surveiller et de contrôler en temps réel les entrées et les sorties de divers capteurs et actionneurs. Par exemple, le Nuvo-2822 peut contrôler les bandes transporteuses, les bras robotisés et les machines à souder, garantissant ainsi des opérations précises et synchronisées. Il peut également collecter des données à partir de capteurs de température et de pression afin de maintenir des conditions optimales pendant la production, ce qui permet de minimiser les défauts et d'accroître l'efficacité.

Grâce à sa capacité à intégrer des cartes d'acquisition d'images compatibles avec l'IA, le Nuvo-2822 peut être utilisé pour l'inspection visuelle en temps réel des produits. Les caméras industrielles à grande vitesse connectées via les ports USB 3.2 Gen 2 du système capturent des images de chaque composant au fur et à mesure qu'il se déplace sur la ligne de production. Ces images sont traitées par des algorithmes d'intelligence artificielle pour détecter les défauts ou les anomalies, garantissant ainsi que seuls les produits de haute qualité atteignent la fin de la ligne.

Le format compact du Nuvo-2822 et sa conception murale lui permettent d'être déployé dans des espaces restreints à proximité de l'équipement de production, réduisant ainsi l'encombrement des câbles et améliorant l'efficacité.

Avantages :

- Productivité accrue : En automatisant des tâches telles que l'assemblage et l'inspection, le Nuvo-2822 réduit les erreurs humaines et augmente la vitesse de production.

- Réduction des coûts : L'automatisation minimise les coûts de main-d'œuvre et réduit le risque de défauts, ce qui permet de réaliser des économies à long terme.

- Efficacité énergétique : Le mode super économie d'énergie garantit que le système consomme un minimum d'énergie pendant les temps d'arrêt, ce qui réduit encore les coûts d'exploitation.

- La vision industrielle pour le contrôle de la qualité

Les systèmes devision industrielle sont essentiels dans les industries où la qualité et la précision des produits sont primordiales. La puissance de calcul haute performance du Nuvo-2822, associée à la prise en charge de cartes d'acquisition d'images compatibles avec l'IA, en fait une plateforme puissante pour les applications de vision industrielle.

Cas d'utilisation : Inspection des emballages pharmaceutiques

Dans l'industrie pharmaceutique, la précision de l'emballage des produits est essentielle pour garantir la sécurité des patients et la conformité aux réglementations. Le Nuvo-2822 peut être déployé sur une ligne d'emballage, où il contrôle des caméras industrielles haute résolution connectées via ses ports USB 3.2 Gen 2. Ces caméras capturent des images de chaque emballage, y compris les étiquettes, les codes-barres et les sceaux des produits.

Avec l'aide d'une carte d'acquisition d'images compatible avec l'IA installée dans l'un des emplacements d'extension PCIe du Nuvo-2822, le système traite ces images en temps réel afin de détecter toute anomalie. Par exemple, il peut vérifier que toutes les étiquettes sont correctement imprimées, que les codes-barres sont lisibles et que les scellés sont intacts.

La carte graphique Intel® UHD intégrée accélère les tâches de traitement des images, tandis que la mémoire DDR5 de 16 Go du système assure une gestion fluide des grands ensembles de données. Si des irrégularités sont détectées, le Nuvo-2822 peut déclencher une sortie DIO isolée pour retirer l'emballage défectueux de la ligne.

Avantages :

- Amélioration du contrôle de la qualité : Les systèmes de vision industrielle alimentés par le Nuvo-2822 offrent un niveau de précision plus élevé que l'inspection manuelle, réduisant ainsi le risque que des produits défectueux atteignent les consommateurs.

- Vitesse accrue : Le traitement des images en temps réel garantit que les produits sont inspectés sans ralentir la ligne de production.

- Conformité : En s'assurant que les emballages sont conformes aux normes réglementaires, le système aide les entreprises pharmaceutiques à éviter les amendes et les rappels coûteux.

- Gestion et contrôle de l'énergie

L'accent étant mis de plus en plus sur le développement durable et l'efficacité énergétique, les industries cherchent des moyens de contrôler et de réduire leur consommation d'énergie. Le Nuvo-2822 peut être utilisé comme système central pour la gestion et la surveillance de l'énergie, en particulier dans les installations dotées de plusieurs machines gourmandes en énergie.

Cas d'utilisation : Surveillance du réseau intelligent dans une usine de fabrication

Dans une grande usine de fabrication, la consommation d'énergie varie considérablement en fonction de l'heure de la journée et des types de machines en fonctionnement. En connectant le Nuvo-2822 à des compteurs intelligents et à des capteurs de puissance dans l'ensemble de l'installation, le système peut collecter des données en temps réel sur la consommation d'énergie.

Grâce à ses multiples ports d'E/S et à ses capacités d'acquisition de données, le Nuvo-2822 peut surveiller la tension, le courant et la consommation d'énergie de diverses machines et équipements. Le système peut également contrôler des interrupteurs automatisés pour éteindre les machines qui ne sont pas utilisées ou réduire la puissance de certaines zones en dehors des heures de pointe.

En outre, la fonctionnalité Wake-on-LAN permet au Nuvo-2822 de réveiller ou d'éteindre à distance des appareils spécifiques, ce qui optimise encore l'utilisation de l'énergie. Le mode super économie d'énergie garantit que le système lui-même consomme un minimum d'énergie lorsqu'il n'est pas utilisé, contribuant ainsi à la réduction globale de la consommation d'énergie de l'établissement.

Avantages :

- Réduction des coûts énergétiques : La surveillance et le contrôle en temps réel de l'utilisation de l'énergie peuvent conduire à des économies d'énergie significatives, en particulier dans les grandes installations où la demande est fluctuante.

- Durabilité : En optimisant la consommation d'énergie, les entreprises peuvent réduire leur empreinte carbone et s'efforcer de respecter l'environnement.

- Amélioration de la longévité des équipements : La surveillance de l'utilisation de l'énergie peut aider à détecter des problèmes tels que la surchauffe ou les surtensions, ce qui permet d'éviter d'endommager l'équipement et de réduire les coûts de maintenance.

- IoT industriel (IIoT) et surveillance à distance

L'essor de l'Internet industriel des objets (IIoT) a transformé la façon dont les processus industriels sont surveillés et contrôlés. Le Nuvo-2822, avec ses riches options de connectivité, notamment Ethernet, les ports série et les DIO isolés, est une plateforme idéale pour créer des applications IIoT.

Cas d'utilisation : Surveillance à distance des oléoducs et gazoducs

Dans l'industrie pétrolière et gazière, la capacité à surveiller les pipelines à distance est essentielle pour prévenir les fuites, assurer la sécurité et optimiser les opérations. Le Nuvo-2822 peut être installé en divers points d'un réseau de pipelines, où il collecte des données provenant de capteurs de pression, de débitmètres et de capteurs de température.

Grâce à ses ports COM et à sa connectivité Ethernet, le système communique avec une salle de contrôle centrale, où les opérateurs peuvent surveiller l'état des pipelines en temps réel. Le Nuvo-2822 peut également déclencher des alarmes ou des arrêts automatiques en cas de chute de pression ou de pic de température, ce qui permet d'éviter des défaillances potentiellement catastrophiques.

En outre, la taille compacte et la conception robuste du système en font un outil idéal pour un déploiement dans des endroits éloignés, où les conditions environnementales peuvent être difficiles. La large plage de températures de fonctionnement garantit que le système peut fonctionner de manière fiable aussi bien dans la chaleur du désert que dans le froid arctique, tandis que la certification MIL-STD-810H garantit la résistance aux chocs et aux vibrations.

Avantages :

- Sécurité accrue : La surveillance à distance permet une détection précoce des problèmes potentiels, réduisant ainsi le risque d'accidents ou de dommages environnementaux.

- Efficacité opérationnelle : En surveillant en permanence l'état des pipelines, les opérateurs peuvent optimiser les débits et réduire la consommation d'énergie.

- Réduction des temps d'arrêt : La possibilité de détecter et de traiter les problèmes à distance minimise la nécessité d'inspections sur site, ce qui réduit les coûts de maintenance et les temps d'arrêt.

- Automatisation de la vente au détail et kiosques en libre-service

Outre les applications industrielles, le Nuvo-2822 peut être utilisé dans le secteur de la vente au détail pour alimenter des kiosques en libre-service, des distributeurs automatiques et d'autres systèmes interactifs.

Cas d'utilisation : caisse libre-service dans un supermarché

Les systèmes de caisse en libre-service sont devenus de plus en plus populaires dans les supermarchés, permettant aux clients de scanner et de payer leurs articles sans avoir besoin d'un caissier. Le Nuvo-2822, avec son processeur haute performance et ses nombreuses options d'E/S, peut servir de cerveau à ces systèmes.

Connecté à des lecteurs de codes-barres, des écrans tactiles et des imprimantes de reçus via ses ports USB et COM, le Nuvo-2822 traite les transactions des clients rapidement et efficacement. Le système peut également être intégré à des terminaux de paiement pour traiter les paiements par carte de crédit en toute sécurité.

En outre, la taille compacte du Nuvo-2822 lui permet d'être facilement intégré dans le boîtier du kiosque, tandis que sa conception économe en énergie garantit qu'il peut fonctionner en continu sans générer de chaleur excessive ou consommer trop d'énergie.

Avantages :

- Amélioration de l'expérience client : Les bornes libre-service réduisent les temps d'attente et permettent aux clients d'effectuer des transactions à leur propre rythme.

- Réduction des coûts de main-d'œuvre : L'automatisation des processus d'encaissement permet aux détaillants d'affecter leur personnel à d'autres tâches, telles que le service à la clientèle ou la gestion des stocks.

- Évolutivité : La conception modulaire de la Nuvo-2822 permet aux commerçants d'étendre facilement leur réseau de bornes en fonction de l'augmentation de la demande.

Conclusion

Le Neousys Nuvo-2822 est un ordinateur industriel polyvalent et robuste qui peut être déployé dans un large éventail d'industries, de la fabrication et de l'automatisation à la vision industrielle, à la gestion de l'énergie et à l'automatisation de la vente au détail. Avec son puissant processeur Intel® Alder Lake N97, ses options d'extension flexibles et son design robuste, le Nuvo-2822 est bien adapté aux exigences des applications industrielles modernes.

Que vous ayez besoin d'un système fiable pour l'automatisation des usines intelligentes, d'une plateforme compatible avec l'IA pour la vision industrielle ou d'une solution compacte pour l'IIoT et la surveillance à distance, le Nuvo-2822 offre les performances, la durabilité et la flexibilité nécessaires pour que vos opérations se déroulent de manière fluide et efficace.

Ses caractéristiques écoénergétiques, sa large plage de températures de fonctionnement et sa robustesse de niveau militaire lui permettent de résister aux environnements difficiles tout en minimisant les coûts opérationnels. En intégrant le Nuvo-2822 à votre infrastructure industrielle, vous pouvez assurer l'avenir de vos opérations et adopter la prochaine génération d'avancées de l'industrie 4.0.