In diesem artikel:

- Einführung

- Hauptmerkmale der DC-1300 Serie

- Vorteile der DC-1300 Serie

- Branchenübergreifende Anwendungen

- Schlussfolgerung: Zukunftssicheres Industrial Computing mit der DC-1300 Serie

Einführung

Der führende Anbieter von robusten Embedded-Computern Cincoze hat seine neueste Innovation in der Rugged Computing - Produktlinie DIAMOND angekündigt: die Serie DC-1300. Dieser neue Industriecomputer der Einstiegsklasse bietet unübertroffene Leistung und Erweiterungsflexibilität in einem kompakten Gehäuse von 185 x 131 x 56,5 mm.

Die DC-1300 Serie wurde entwickelt, um den Herausforderungen in platzbeschränkten Industrieumgebungen gerecht zu werden. Sie verfügt über fortschrittliche Verarbeitungsleistung, robuste E/A-Funktionen und umfassende drahtlose Anschlussmöglichkeiten, die eine nahtlose Integration in intelligente Fertigungs- und Industrieautomatisierungsanwendungen gewährleisten.

Hauptmerkmale der DC-1300 Serie

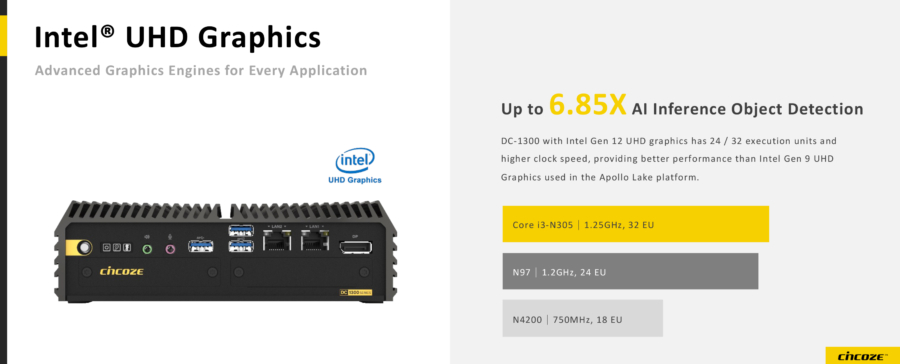

- Leistung der nächsten Generation mit Intel® Alder Lake-N-Prozessor Die DC-1300 Serie basiert auf der Intel® Alder Lake-N-Plattform und unterstützt den Intel® Core™ i3-N305-Prozessor, der eine 4,5-fache Leistungssteigerung im Vergleich zu seinem Vorgänger bietet. Dank dieser verbesserten Verarbeitungsleistung kann das System eine Vielzahl anspruchsvoller industrieller Arbeitslasten bewältigen, wie z. B. Datenerfassung in Echtzeit, maschinelle Lernalgorithmen, KI-gesteuerte Robotik und Prozessoptimierung. Ganz gleich, ob es um die Verwaltung vorausschauender Wartungssysteme, die Steuerung von Hochgeschwindigkeits-Produktionslinien oder die Ausführung anspruchsvoller Bildverarbeitungsanwendungen geht, der DC-1300 sorgt für einen reibungslosen Betrieb.

Die fortschrittliche Architektur des Prozessors wird durch bis zu 16 GB DDR5-Speicher mit 4800 MHz ergänzt, der die erforderliche Bandbreite für Multitasking und datenintensive Prozesse bietet, die in modernen Industrieumgebungen üblich sind.

Die DC-1300 Serie basiert auf der Intel® Alder Lake-N Plattform und unterstützt den Intel® Core™ i3-N305 Prozessor, der die 4,5-fache Rechenleistung seines Vorgängers bietet. Dieser leistungsstarke Prozessor ist auf industrielle Workloads wie Datenerfassung, Echtzeit-Analytik und KI-gesteuerte Automatisierung zugeschnitten und sorgt für hohe Effizienz bei anspruchsvollen Anwendungen. In Kombination mit der Unterstützung von bis zu 16 GB DDR5-Speicher mit 4800 MHz in einem einzigen Steckplatz ist dieses System für die mühelose Bewältigung intensiver Aufgaben ausgelegt.

- Kompaktes und dennoch leistungsfähiges Design

Der DC-1300 zeichnet sich durch seine effiziente Raumnutzung aus, mit einer bemerkenswert kompakten Grundfläche von nur 185 x 131 x 56,5 mm. Dies macht ihn zu einer idealen Lösung für Umgebungen mit begrenztem Platzangebot, wie z.B. Produktionslinien, Roboterarbeitsplätze oder andere Maschinen mit eingeschränktem Layout.

Trotz seiner geringen Größe bietet der DC-1300 eine außergewöhnliche Rechenleistung, die es mit wesentlich größeren Systemen aufnehmen kann. Dank seiner robusten Leistungsmerkmale eignet er sich besonders gut für Aufgaben in der Fabrikautomatisierung und ermöglicht eine nahtlose Integration in industrielle Anlagen und Prozesse. Dank seiner hohen Effizienz und Zuverlässigkeit eignet er sich außerdem perfekt für die Steuerung von Robotern, bei denen Präzision und gleichbleibende Leistung von größter Bedeutung sind.

Ob in engen Gehäusen oder eingebettet in platzbeschränkte Maschinen, der DC-1300 bietet ein harmonisches Gleichgewicht zwischen kompaktem Design und leistungsstarker Funktionalität und ermöglicht der Industrie Innovationen ohne Kompromisse bei Platz oder Leistung.

- Flexible Lagerungsoptionen

Der DC-1300 wurde mit Blick auf Vielseitigkeit entwickelt und bietet eine Reihe von Speicherkonfigurationen, die den unterschiedlichsten industriellen Anforderungen gerecht werden. Er unterstützt sowohl 2,5-Zoll-SATA-HDD/SSD als auch Half-Slim-SSD und bietet damit zuverlässige Optionen für die Langzeitarchivierung oder weniger anspruchsvolle Daten-Workloads.

Für Anwendungen, die einen blitzschnellen Datenzugriff und höhere Leistung erfordern, ist der DC-1300 mit einem M.2-Steckplatz ausgestattet, der die Verwendung von NVMe-SSDs ermöglicht. Diese Hochgeschwindigkeitslaufwerke gewährleisten außergewöhnliche Lese- und Schreibgeschwindigkeiten und sind daher ideal für Echtzeit-Datenverarbeitung, Analysen und große industrielle Arbeitslasten.

Dank dieser Speicherflexibilität lässt sich der DC-1300 nahtlos an eine Vielzahl von Anwendungsfällen anpassen:

- Hochgeschwindigkeits-Datenverarbeitung: Perfekt für Umgebungen wie Fabrikautomation oder Robotik, wo der Echtzeitdatenzugriff für die Steuerung von Geräten oder die Verarbeitung von Sensoreingaben entscheidend ist.

- Datenarchivierung und -speicherung: Ideal für Szenarien, die eine langfristige Datenaufbewahrung erfordern, z. B. Überwachungsgeräteprotokolle, Produktionsaufzeichnungen oder Videomaterial von Überwachungssystemen.

- Anpassbare Lösungen: Durch die Möglichkeit, verschiedene Speichertypen zu kombinieren, können die Benutzer das System so anpassen, dass Leistung, Kapazität und Kosten ihren spezifischen Anforderungen entsprechen.

Weitere Vorteile sind:

- Skalierbarkeit: Erweiterbare Speicheroptionen zur Anpassung an den wachsenden Datenbedarf.

- Verlässlichkeit: Die Unterstützung von SSDs in Industriequalität gewährleistet einen stabilen Betrieb bei extremen Temperaturen oder in Umgebungen mit starken Vibrationen.

- Energie-Effizienz: Entwickelt, um den Stromverbrauch auch bei Hochleistungsspeicherkonfigurationen zu optimieren.

Durch die Integration fortschrittlicher Speicheroptionen bietet der DC-1300 eine robuste Grundlage für die Bewältigung der komplexen Datenanforderungen moderner Industrieanwendungen. Ganz gleich, ob Geschwindigkeit, Kapazität oder Haltbarkeit im Vordergrund stehen, dieses kompakte System bietet Flexibilität ohne Kompromisse.

- Umfangreiche native E/A-Schnittstellen

Der DC-1300 wurde speziell für die nahtlose Integration in industrielle Ökosysteme entwickelt und verfügt über ein umfangreiches Angebot an nativen E/A-Schnittstellen zur Unterstützung verschiedener betrieblicher Anforderungen. Seine Konnektivitätsoptionen umfassen:

- Mehrere LAN-Anschlüsse: Diese ermöglichen eine zuverlässige Hochgeschwindigkeitsvernetzung und unterstützen Redundanz oder mehrere Netzwerkkonfigurationen, ideal für die Verbindung mit IoT-Geräten oder die Verwaltung industrieller Netzwerke.

- USB-Anschlüsse: Hochgeschwindigkeits-USB-Anschlüsse ermöglichen eine einfache Verbindung mit externen Geräten wie Barcode-Scannern, Datenloggern und tragbaren Speicherlaufwerken.

- COM-Anschlüsse: Die COM-Anschlüsse sind für die Kompatibilität mit älteren Geräten unverzichtbar und ermöglichen die nahtlose Kommunikation mit älteren Industriegeräten, einschließlich speicherprogrammierbaren Steuerungen (SPS) und CNC-Maschinen.

- 4K-fähiger DisplayPort-Ausgang: Der DisplayPort-Ausgang unterstützt kristallklare Bilder und ermöglicht den Anschluss von hochauflösenden Displays für Überwachung, Diagnose oder Benutzeroberflächen und erfüllt damit die Anforderungen moderner industrieller Kontrollräume.

Diese Schnittstellen machen den DC-1300 äußerst anpassungsfähig für den Anschluss einer breiten Palette von Geräten und Peripheriegeräten und ermöglichen es der Industrie, den Betrieb zu modernisieren, ohne die bestehenden Einrichtungen zu überholen.

Wichtige Anwendungsfälle:

- Sensor-Netzwerke: Mit mehreren Anschlüssen kann der DC-1300 als zentraler Knotenpunkt für die Erfassung von Echtzeitdaten von Sensoren fungieren, was ihn ideal für Umgebungen wie intelligente Fabriken oder automatisierte Lagerhäuser macht.

- Steuerungssysteme: Seine vielseitigen E/A-Optionen ermöglichen die Integration sowohl in moderne als auch in ältere Steuerungssysteme und gewährleisten so die Betriebskontinuität bei Upgrades oder Umstellungen.

- Industrielle Überwachung: Durch die Unterstützung von 4K-Displays eignet sich das System perfekt für hochauflösende Dashboards und Bedienfelder und verbessert die Echtzeitvisualisierung von Daten und Prozessen.

- Edge-Computing: Mehrere LAN- und COM-Ports ermöglichen es dem DC-1300, verteilte Datenverarbeitungsaufgaben am Rande des Netzwerks zu bewältigen, wodurch die Latenzzeit verringert und die Entscheidungsfindung beschleunigt wird.

Vorteile der umfangreichen E/A-Schnittstellen:

- Flexibilität: Ermöglicht die Kompatibilität mit einer Vielzahl von industriellen Peripheriegeräten, von Sensoren und Aktoren bis hin zu modernen Displays.

- Zukunftssicher: 4K-fähiger DisplayPort gewährleistet die Kompatibilität mit Display-Standards der nächsten Generation.

- Effiziente Upgrades: Unterstützt die Integration mit älteren Geräten und reduziert so Kosten und Ausfallzeiten bei Systemerweiterungen.

Die robusten Konnektivitätsoptionen des DC-1300machen ihn zu einem unschätzbaren Werkzeug für moderne Industriebetriebe, das die Lücke zwischen Altsystemen und Spitzentechnologien überbrückt und gleichzeitig die Effizienz und Zuverlässigkeit maximiert.

- Stapelbare Erweiterungsbox (SEB)

Mit der Einführung der stapelbaren Erweiterungsbox (Stackable Expansion Box, SEB) erreicht die DC-1300 Serie eine neue Stufe der Anpassungsfähigkeit. Dieses innovative Design nutzt die dualen M.2 B Key-Steckplätze des Systems und ermöglicht eine modulare Erweiterbarkeit, die einer Vielzahl von industriellen Anforderungen gerecht wird. Die SEB bietet eine nahtlose Integration mit spezialisierten Modulen, darunter:

- E/A-Module: Zur Erhöhung der Anzahl von Eingangs-/Ausgangsschnittstellen für komplexes Gerätemanagement.

- CANbus-Module: Unverzichtbar für Anwendungen, die eine robuste Kommunikation in Automobil- oder industriellen Automatisierungssystemen erfordern.

- Feldbus-Module: Entwickelt für fortschrittliche Industrienetzwerke, die Kompatibilität mit speziellen Kommunikationsprotokollen wie PROFIBUS, EtherCAT oder Modbus ermöglichen.

Die wichtigsten Vorteile der SEB:

- Anpassbarer modularer Aufbau: Benutzer können das System durch die Integration zusätzlicher Sensoren, Kommunikationsprotokolle oder Schnittstellen an ihre betrieblichen Anforderungen anpassen.

- Verbesserte Skalierbarkeit: Das stapelbare Design sorgt für eine einfache und platzsparende Erweiterung und ermöglicht zukünftige Upgrades, ohne dass die gesamte Einrichtung überholt werden muss.

- Kosteneffiziente Anpassungsfähigkeit: Die Modularität macht die Investition in mehrere eigenständige Systeme überflüssig, was die Kosten senkt und gleichzeitig die Flexibilität erhält.

Industrielle Anwendungen:

- Intelligente Fertigung

- Die SEB ermöglicht die Echtzeit-Datenerfassung von modernen Maschinen und unterstützt die vorausschauende Wartung und Produktionsoptimierung.

- Erweiterte E/A-Funktionen gewährleisten die nahtlose Verwaltung mehrerer Geräte, wie z. B. Roboterarme, Förderbänder und Überwachungssysteme.

- Intelligenter Transport

- Telemetrie-Integration: Die SEB kann die Fahrzeugdiagnose durch die Integration von Telemetriesystemen verbessern und ermöglicht so Flottenmanagementlösungen, die Einblicke in die Kraftstoffeffizienz, den Wartungsbedarf und die Routenoptimierung bieten.

- Die Kompatibilität mit CANbus-Modulen sorgt für eine effiziente Kommunikation zwischen den Teilsystemen des Fahrzeugs und erhöht die Zuverlässigkeit.

- Energiemanagement

- Der SEB ermöglicht die Integration spezieller Feldbusmodule, die für die Überwachung und Optimierung der Energieverteilung in erneuerbaren Energiesystemen wie Solarparks und Windturbinen entscheidend sind.

- Es unterstützt die nahtlose Integration mit Energieüberwachungssystemen, die eine detaillierte Verfolgung von Leistungskennzahlen und die Maximierung der Effizienz ermöglichen.

Zukunftssichere Flexibilität:

Mit seiner stapelbaren und modularen Architektur verwandelt der SEB den DC-1300 in eine äußerst anpassungsfähige und zukunftssichere Plattform. Die SEB stellt sicher, dass das System mit neuen Technologien und wachsenden betrieblichen Anforderungen Schritt halten kann, wenn sich die Industrie weiterentwickelt. Ob es um die Integration der neuesten industriellen Kommunikationsstandards oder um das Hinzufügen neuer Funktionen für spezielle Anwendungsfälle geht, die SEB bietet eine skalierbare und zuverlässige Lösung.

Das SEB für die DC-1300 Serie ermöglicht Unternehmen Innovationen und Anpassungen und erschließt neue Möglichkeiten in Branchen wie der Fertigung, dem Transportwesen und dem Energiemanagement - und das alles unter Beibehaltung der Zuverlässigkeit und Effizienz, für die Cincoze bekannt ist.

- Drahtlose Konnektivität für intelligente Lösungen

Der DC-1300 wurde entwickelt, um die Anforderungen moderner industrieller Anwendungen zu erfüllen, indem er robuste drahtlose Konnektivitätsoptionen bietet, einschließlich Wi-Fi, 5G und GNSS. Diese fortschrittlichen Technologien ermöglichen eine zuverlässige und schnelle Datenübertragung und machen den DC-1300 zu einer idealen Lösung für IoT-fähige Systeme, intelligente Geräte und verteilte industrielle Netzwerke.

Drahtlose Schlüsseltechnologien:

- Wi-Fi

- Sorgt für nahtlose lokale Konnektivität und ermöglicht die Kommunikation zwischen Geräten und Systemen in einer Fabrik, einem Lager oder einem Büro.

- Perfekt für die gemeinsame Nutzung von Daten in Echtzeit, die einen schnellen Zugriff auf Systemdiagnosen, Fernsteuerungen oder die Cloud-Integration ermöglichen, ohne dass kabelgebundene Verbindungen erforderlich sind.

- 5G

- Liefert ultraschnelle Datengeschwindigkeiten und niedrige Latenzzeiten, die für die Echtzeitüberwachung, die Verarbeitung großer Datenmengen und zeitkritische industrielle Anwendungen unerlässlich sind.

- Ideal für Anwendungen, die massive IoT-Implementierungen erfordern, wie z. B. intelligente Städte, autonome Fahrzeuge oder Hochgeschwindigkeits-Transportsysteme.

- GNSS (Globales Navigationssatellitensystem)

- Unterstützt die genaue Standortverfolgung und ist damit eine wichtige Voraussetzung für das Flottenmanagement, autonome Fahrzeuge und industrielle Außeneinsätze.

- Bietet die erforderliche Präzision für Anwendungen wie intelligente Logistik, Navigation und Geodatenanalyse.

Industrielle Anwendungen:

- Intelligente Fertigung

- Drahtlose Konnektivität ermöglicht die Echtzeitüberwachung von Produktionslinien und -anlagen durch IoT-fähige Sensoren.

- Erleichtert die nahtlose Kommunikation zwischen Maschinen und sorgt so für betriebliche Effizienz und geringere Ausfallzeiten.

- Intelligenter Transport und Logistik

- 5G- und GNSS-Technologien sind für das Flottenmanagement von entscheidender Bedeutung und ermöglichen detaillierte Fahrzeugdiagnosen, Routenoptimierung und Echtzeitverfolgung.

- Unterstützt die autonome Fahrzeugkommunikation und sorgt für eine reibungslose Navigation und verbesserte Sicherheit.

- Energie-Fernmanagement

- Wi-Fi und 5G ermöglichen die Fernüberwachung und -steuerung von Systemen zur Nutzung erneuerbarer Energien, wie z. B. Solarparks oder Windkraftanlagen.

- Die GNSS-Integration hilft bei der Verfolgung und Verwaltung mobiler Energieplattformen oder entfernter Anlagen.

- Intelligente Städte

- Die Wireless-Funktionen des DC-1300 ermöglichen Anwendungen wie intelligente Verkehrssysteme, öffentliche Verkehrsnetze und Umweltüberwachung.

- Ermöglicht die nahtlose Kommunikation zwischen IoT-Geräten und schafft so effiziente und vernetzte städtische Umgebungen.

Vorteile der drahtlosen Konnektivität:

- Flexibilität: Es ist keine umfangreiche Verkabelung erforderlich, was die Komplexität und die Kosten der Installation reduziert.

- Skalierbarkeit: Unterstützt wachsende Netzwerke von IoT-Geräten, so dass Unternehmen ihren Betrieb problemlos erweitern können.

- Daten in Echtzeit: Ermöglicht den sofortigen Zugriff auf wichtige Erkenntnisse und verbessert so die Entscheidungsfindung und die betriebliche Effizienz.

- Verlässlichkeit: Entwickelt für stabile und sichere Verbindungen, selbst in anspruchsvollen industriellen Umgebungen.

Durch die Integration fortschrittlicher drahtloser Technologien erleichtert der DC-1300 die Entwicklung intelligenter Lösungen, die herkömmliche industrielle Prozesse revolutionieren. Ob in der Fertigung, in der Logistik oder im Energiesektor, seine drahtlosen Funktionen gewährleisten eine unterbrechungsfreie Kommunikation und einen Datenfluss über verteilte Netzwerke und ebnen so den Weg für Innovation und Effizienz.

- Robuste Langlebigkeit

Der DC-1300 wurde speziell für den zuverlässigen Einsatz in rauen und anspruchsvollen Industrieumgebungen entwickelt. Mit seinem robusten Design und der Einhaltung strenger Normen gewährleistet er Betriebsstabilität auch unter schwierigsten Bedingungen.

Wichtige Merkmale der Langlebigkeit:

- Großer Temperaturbereich

- Der DC-1300 kann in einem Temperaturbereich von -40°C bis 70°C betrieben werden und ist damit sowohl für eisige Kälte als auch für sengende Hitze geeignet.

- Ideal für den Einsatz im Freien, in Kühleinrichtungen, unter wüstenähnlichen Bedingungen oder in temperaturempfindlichen Produktionsanlagen.

- Breiter Spannungseingang

- Durch die Unterstützung eines Eingangsbereichs von 9-48 VDC ist der DC-1300 mit einer Vielzahl von Stromquellen kompatibel, einschließlich instabiler oder schwankender industrieller Stromsysteme.

- Dies gewährleistet eine gleichbleibende Leistung in Umgebungen wie Transportwesen, abgelegenen Einrichtungen und mobilen Installationen.

- EMC-Konformität

- Durch die Einhaltung der IEC 61000-6-2/4 EMV-Normen ist der DC-1300 resistent gegen elektromagnetische Interferenzen (EMI), was eine unterbrechungsfreie Leistung in elektrisch lauten Umgebungen wie Fabriken oder Kraftwerken gewährleistet.

- Schockresistenz nach Militärstandard

- Der DC-1300 ist nach dem US-Militärschockstandard (MIL-STD-810H) zertifiziert und widersteht starken Vibrationen und Stößen.

- Dadurch eignet er sich für Anwendungen mit starken Vibrationen, wie z. B. in Fahrzeugsystemen, schweren Maschinen und Industrierobotern.

Industrielle Anwendungen:

- Intelligente Fertigung

- Dank seines robusten Designs kann der DC-1300 in Umgebungen eingesetzt werden, die anfällig für Vibrationen, elektrisches Rauschen oder extreme Temperaturen sind, z. B. in Gießereien, CNC-Bearbeitungswerkstätten und Montagelinien.

- Transport und Logistik

- Sein breiter Spannungseingang und seine Stoßfestigkeit machen ihn ideal für Fahrzeugsysteme, einschließlich Flottenmanagement, Überwachung öffentlicher Verkehrsmittel und Telematik.

- Er eignet sich für den Einsatz in Schienenfahrzeugen oder Geländewagen, wo ein gleichmäßiger Betrieb unter Vibrationen und Leistungsschwankungen entscheidend ist.

- Energie und Versorgungsunternehmen

- Der DC-1300 kann an abgelegenen Standorten oder im Freien installiert werden, z. B. in Windparks, Solaranlagen oder auf Bohrinseln, wo er extremen Temperaturen und rauen Wetterbedingungen standhalten muss.

- Verteidigung und Luft- und Raumfahrt

- Die MIL-STD-810H-Zertifizierung stellt sicher, dass der DC-1300 für missionskritische Anwendungen, wie Bodenfahrzeuge, Drohnen oder mobile Kommandoeinheiten, zuverlässig ist.

Vorteile der robusten Langlebigkeit:

- Ununterbrochene Leistung: Konstanter Betrieb in extremen Umgebungen, reduzierte Ausfallzeiten und hohe Zuverlässigkeit bei einsatzkritischen Aufgaben.

- Verlängerte Lebensdauer: Entwickelt, um rauen Bedingungen standzuhalten, wodurch Wartungskosten und die Notwendigkeit eines häufigen Austauschs reduziert werden.

- Vielseitiger Einsatz: Kann in verschiedenen Branchen mit unterschiedlichen Umweltbedingungen eingesetzt werden, von extremer Hitze bis hin zu starken Vibrationen.

- Sicherheit und Konformität: EMV- und Militärstandards gewährleisten den sicheren und effizienten Betrieb des Systems, selbst in sensiblen oder regulierten Umgebungen.

Durch die Kombination von robuster Widerstandsfähigkeit und fortschrittlichen Computerfunktionen ist der DC-1300 eine zuverlässige Lösung für Branchen, in denen es auf Widerstandsfähigkeit unter extremen Bedingungen ankommt. Sein robustes Design gewährleistet nicht nur eine zuverlässige Leistung, sondern macht ihn auch zu einer langfristigen Investition für kritische industrielle Anwendungen.

Vorteile der DC-1300 Serie

Verbesserte Leistung für die industrielle Automatisierung

Die DC-1300 Serie bietet überragende Leistung, angetrieben von der Intel® Alder Lake-N Plattform, die eine 4,5-fache Steigerung der Verarbeitungsleistung bietet. Diese verbesserte Architektur gewährleistet einen reibungslosen Betrieb bei anspruchsvollen industriellen Aufgaben und macht sie zu einer idealen Lösung für industrielle Automatisierungsanwendungen.

- Vorausschauende Wartung: Das System verarbeitet Sensordaten in Echtzeit, um Anlagenausfälle vorherzusagen, Ausfallzeiten zu reduzieren und die Kosten für ungeplante Reparaturen zu senken. Seine leistungsstarken Rechenfunktionen gewährleisten präzise Analysen und effiziente Entscheidungsfindung und steigern so die betriebliche Gesamteffizienz.

- Robotik-Steuerung: Die fortschrittliche Rechenleistung des DC-1300 ermöglicht die nahtlose Ausführung von KI-gesteuerten Algorithmen, die eine präzise Steuerung von Robotern in Fließbändern, bei der Materialhandhabung und in Logistikprozessen gewährleisten.

- Bildverarbeitungsanwendungen: Hochauflösende Bildverarbeitung für Qualitätsprüfungen, Fehlererkennung und Sortieraufgaben wird durch die erweiterte Verarbeitungskapazität des Systems unterstützt. Dies ist entscheidend für die Einhaltung hoher Produktqualitätsstandards in der modernen Fertigung.

- KI-gestützte Analytik: Dank seiner Multitasking-Fähigkeiten eignet sich der DC-1300 ideal für Bedarfsprognosen, die Optimierung der Lieferkette und andere KI-gesteuerte Prozesse zur Optimierung der Produktionsabläufe.

Durch die Nutzung der Intel® Alder Lake-N-Plattform gewährleistet der DC-1300 einen zuverlässigen, leistungsstarken Betrieb für Aufgaben wie Echtzeitverarbeitung, Robotersteuerung und maschinelles Sehen und hilft Unternehmen, die Betriebszeit aufrechtzuerhalten und die Produktionseffizienz zu optimieren.

Platzsparendes Design für vielseitige Einsetzbarkeit

Der DC-1300 wurde für Umgebungen mit begrenztem Platzangebot entwickelt und verfügt über kompakte Abmessungen und mehrere Montageoptionen, einschließlich Wand-, Seiten- und DIN-Schienenmontage. Diese Vielseitigkeit ermöglicht den Einsatz in engen Räumen wie Schaltschränken, fahrerlosen Transportsystemen (FTS) und Maschinen.

Sein platzsparendes Design macht ihn zur idealen Lösung für intelligente Fabriken und moderne Automatisierungssysteme, bei denen Effizienz und Anpassungsfähigkeit im Vordergrund stehen. Die kompakte Bauweise gewährleistet eine nahtlose Integration ohne Kompromisse bei der Leistung.

Zuverlässiger Betrieb in rauen Umgebungen

Der DC-1300 wurde entwickelt, um den härtesten industriellen Bedingungen standzuhalten und bietet:

- Breiter Temperaturbereich (-40°C bis 70°C): Gewährleistet einen stabilen Betrieb bei extremer Hitze oder Kälte.

- Breiter Spannungseingang (9-48 VDC): Ermöglicht die Kompatibilität mit verschiedenen Stromquellen, auch in instabilen Umgebungen.

- Konformität mit Industriestandards: Erfüllt die EMV-Normen (IEC 61000-6-2/4) und die Norm MIL-STD-810H für Stoßfestigkeit und garantiert so eine zuverlässige Leistung in Umgebungen mit Vibrationen, elektrischem Rauschen oder anderen Herausforderungen.

Diese robuste Widerstandsfähigkeit gewährleistet einen unterbrechungsfreien Betrieb an abgelegenen Orten, in rauen Industrieanlagen oder Transportsystemen und macht den DC-1300 zu einer zuverlässigen Wahl für kritische Anwendungen.

Zukunftssichere Flexibilität

Der DC-1300 ist modular erweiterbar, so dass sich Unternehmen an die sich entwickelnde Technologie und die Anforderungen der Branche anpassen können. Zu den wichtigsten Merkmalen gehören:

- M.2-Erweiterung: Unterstützt Hochgeschwindigkeits-NVMe-Speicher oder zusätzliche drahtlose Konnektivitätsmodule, wie Wi-Fi oder 5G.

- Stapelbare Add-Ons: Ermöglicht die nahtlose Integration von Spezialmodulen wie CANbus, Feldbus oder zusätzlichen E/A-Schnittstellen und verbessert so die Anpassungsfähigkeit des Systems.

Diese zukunftssichere Flexibilität ermöglicht es Unternehmen,:

- Integration neuer Sensoren oder Technologien für eine verbesserte Automatisierung.

- Upgrade der Konnektivität oder der Verarbeitungsfunktionen bei wachsenden Anforderungen.

- Erweiterung des Funktionsumfangs, um neuen Anwendungsfällen gerecht zu werden und sicherzustellen, dass das System langfristig relevant und kosteneffizient bleibt.

Mit ihrem kompakten Design, ihrer Robustheit und ihrer hohen Leistung ist die DC-1300 Serie eine zuverlässige und skalierbare Lösung für die moderne Industrieautomation, die intelligente Fabriken, Echtzeit-Analysen und IoT-gesteuerte Prozesse ermöglicht.

Branchenübergreifende Anwendungen

Intelligente Fertigung

Die DC-1300 Serie revolutioniert die industrielle Automatisierung, indem sie die Effizienz von Produktionslinien durch fortschrittliche Echtzeit-Überwachungs-, Steuerungs- und Konnektivitätsfunktionen verbessert. Sie ermöglicht:

- Fortschrittliche Robotiksysteme: Intelligente Robotik für präzise Fließbandaufgaben und Materialhandling.

- Vorausschauende Wartung: Analyse von Sensordaten zur Vorhersage von Anlagenproblemen, Minimierung von Ausfallzeiten und Reduzierung von Wartungskosten.

- Intelligente Überwachung: Optimierung der Produktionsabläufe und Gewährleistung einer konsistenten Fabrikautomation.

Das robuste Design ist für anspruchsvolle Umgebungen ausgelegt und gewährleistet eine hohe Zuverlässigkeit, selbst unter rauen Produktionsbedingungen, was es zu einer entscheidenden Komponente von Smart-Factory-Lösungen macht.

Intelligenter Transport

Der DC-1300 wurde für die Herausforderungen intelligenter Transportsysteme entwickelt und bietet außergewöhnliche drahtlose Konnektivität und modulare Erweiterungsmöglichkeiten. Zu den wichtigsten Anwendungen gehören:

- Flottenmanagement: Umfassende Fahrzeugdiagnose, vorausschauende Wartung und Sicherstellung von Spitzenleistungen.

- Routen-Optimierung: Nutzung von GNSS-Funktionen für die Echtzeit-Navigation, Reduzierung des Kraftstoffverbrauchs und Verbesserung der logistischen Effizienz.

- Öffentlicher Verkehr: Unterstützung von fortschrittlicher Telemetrie für Fahrgastinformationssysteme, die dynamische Aktualisierungen von Fahrplänen und Routen bieten.

Mit CANbus- und Feldbus-Unterstützung eignet sich der DC-1300 hervorragend für intelligente Transportsysteme und ermöglicht eine effiziente Verfolgung, Diagnose und Kommunikation in Logistikzentren und öffentlichen Verkehrsnetzen.

Energiemanagement

Das robuste Design des DC-1300 und seine Fähigkeit, unter extremen Bedingungen zu arbeiten, machen ihn zur perfekten Lösung für Anwendungen im Bereich der erneuerbaren Energien, wie z.B. Wind- und Solarparks. Seine Funktionen umfassen:

- Energie-Überwachung: Verfolgung der Produktionsdaten zur Optimierung der Netzintegration.

- Datenanalyse: Bereitstellung umsetzbarer Erkenntnisse zur Verbesserung der Energienutzung.

- Ferndiagnose: Unterstützung der Fernsteuerung und Fehlersuche für Stromverteilungssysteme.

Diese Anpassungsfähigkeit sorgt für ein effizientes und zuverlässiges Energiemanagement in unterschiedlichen Umgebungen, von städtischen Netzen bis hin zu abgelegenen Energiestandorten.

Gesundheitswesen

Die DC-1300 Serie bietet dank ihrer hohen Rechenleistung und ihres kompakten Formfaktors eine außergewöhnliche Leistung für Anwendungen im Gesundheitswesen. Zu den wichtigsten Vorteilen gehören:

- Medizinische Bildgebung: Schnelle und präzise Verarbeitung hochauflösender Bilder für Diagnosegeräte.

- Patientenüberwachung: Unterstützung von Echtzeit-Datenerfassung und -Warnungen für kritische Pflegesituationen.

- Verlässlichkeit: Das robuste Design gewährleistet einen unterbrechungsfreien Betrieb in sensiblen Umgebungen im Gesundheitswesen.

Seine kompakte Größe und robuste Leistung machen ihn für moderne medizintechnische Lösungen unverzichtbar.

IoT und Edge Computing

Als IoT-Gateway unterstützt der DC-1300 unter anderem Smart-City- und Edge-Computing-Anwendungen:

- Intelligente Kioske: Verbesserung von Bürgerdiensten durch Echtzeit-Datenverarbeitung.

- Umweltüberwachung: Verfolgung von Luftqualität, Wettermustern und anderen wichtigen Daten.

- Gebäude-Management-Systeme: Verbindung und Steuerung intelligenter Gebäudeinfrastrukturen.

Mit umfassender Konnektivität und der Fähigkeit, Daten in Echtzeit zu übertragen, ist der DC-1300 ein Eckpfeiler von IoT-gesteuerten Ökosystemen und Edge-Computing-Architekturen.

Einzelhandel und Gastgewerbe

Die DC-1300 Serie transformiert Einzelhandels- und Gastgewerbeumgebungen, indem sie folgende Funktionen bietet

- Selbstbedienungs-Kioske: Ermöglicht reibungsloses Einchecken von Kunden in Hotels und an Serviceschaltern.

- Interaktive digitale Beschilderung: Bereitstellung von personalisierten Werbe- und Promotion-Inhalten.

- Point-of-Sale-Systeme: Bestandsverwaltung in Echtzeit und Verbesserung des Kundenerlebnisses.

Ihr kompaktes, robustes Design macht sie zu einer zuverlässigen Lösung für stark frequentierte Bereiche mit Kundenkontakt.

Automatisch gesteuerte Fahrzeuge (AGVs)

Die DC-1300 Serie ist perfekt für fahrerlose Transportsysteme in Lagern und Fabriken geeignet. Sie unterstützt:

- Navigationssysteme: Für eine präzise Routenplanung und -optimierung.

- Nahtlose Kommunikation: Ermöglicht eine effiziente Koordination mit zentralen Steuerungssystemen.

- Effizienter Materialumschlag: Rationalisierung der Logistikabläufe durch Datenintegration in Echtzeit.

Mit seiner robusten Langlebigkeit und kompakten Bauweise verbessert der DC-1300 die Leistung und Zuverlässigkeit von FTS-Lösungen und steigert die betriebliche Effizienz in der intelligenten Fertigung und Logistik.

Schlussfolgerung: Zukunftssicheres Industrial Computing mit der DC-1300 Serie

Die DC-1300 Serie zeichnet sich als vielseitige und zuverlässige Lösung für eine Vielzahl industrieller Anwendungen aus und bietet die perfekte Kombination aus starker Leistung, kompaktem Design und robuster Haltbarkeit. Ob zur Steigerung der Produktionseffizienz in der intelligenten Fertigung, zur Ermöglichung eines nahtlosen Flottenmanagements im intelligenten Transportwesen oder zur Optimierung von Systemen für erneuerbare Energien - der DC-1300 erfüllt die Anforderungen moderner Industrieumgebungen in hervorragender Weise.

Mit seiner Intel® Alder Lake-N-Plattform, modularer Erweiterbarkeit und fortschrittlichen Konnektivitätsoptionen wie Wi-Fi, 5G und GNSS bietet der DC-1300 zukunftssichere Flexibilität für IoT-getriebene Ökosysteme und KI-gestützte Anwendungen. Seine Fähigkeit, extremen Bedingungen standzuhalten, und seine Konformität mit strengen Standards machen ihn zu einer zuverlässigen Wahl für Branchen, die einen unterbrechungsfreien Betrieb in rauen Umgebungen erfordern.

Vom Gesundheitswesen und Einzelhandel bis hin zum Energiemanagement und Edge Computing bietet der DC-1300 eine unübertroffene Leistung und Anpassungsfähigkeit, die es Unternehmen ermöglicht, die Automatisierung voranzutreiben, die betriebliche Effizienz zu verbessern und in einer zunehmend vernetzten Welt die Nase vorn zu haben.

Für Unternehmen, die einen robusten, skalierbaren und zukunftssicheren Industriecomputer suchen, ist die Cincoze DC-1300 Serie die beste Wahl.