In this article:

The Client

The mining industry, traditionally characterised by manual labour and conventional methods, is now embracing a technological revolution, driven by the integration of advanced IoT, AI, and autonomous robotics; Mining 4.0.

Dr Cámara Rascón, a Ph.D. in Mine Engineering and a leading professor, identifies the essential technologies for achieving Mining 4.0: automation and robotics, artificial intelligence, IoT, specialised sensors, drones, digital twins, virtual reality, and the utilisation of mining cavities for energy transmission and storage. These innovations are set to enhance safety, efficiency, sustainability, and reduce the dependency on human labour in mining operations.

A major mining company sought to upgrade their operations by implementing Autonomous Mobile Robots (AMRs) and haulers to streamline their processes. This involved the need for sophisticated AMR controllers capable of handling the complexities of autonomous operations in an open-pit mining environment.

The Demands of the Application

To enhance their ore and waste transportation processes without human intervention, the client required advanced AMR controllers. These controllers were necessary to ensure that automated vehicles could navigate mining sites efficiently and safely, equipped with advanced sensors for path planning, obstacle avoidance, and GPS tracking. The deployment of autonomous haulage trucks promised several benefits, including 24/7 operation, reduced accident risks, optimised fuel consumption, and increased productivity.

Additionally, the client needed AMR controllers for robots tasked with drilling and blasting—activities that are inherently hazardous. Autonomous robots allow these tasks to be performed remotely, significantly enhancing worker safety. These robots, equipped with GPS and vision systems, navigate and plan paths with high precision, transmitting data back to the control centre to optimise drilling accuracy and speed.

Traditional mining exploration methods are often laborious, costly, and dangerous. With growing sustainability demands and labour shortages, robotic exploration has become essential. These robots can safely explore unstable or flooded tunnels, mitigating risks to human workers. Exploration robots come in various forms, such as rovers, drones, and submarine robots, all equipped with sensors, cameras, and wireless connectivity to relay data to control centres.

The Solution

Axiomtek, a leader in industrial computer and embedded system design and manufacturing, provided an ideal solution with their high-performance edge AI AMR controllers—the AIE510-ONX and ROBOX500. These controllers are designed to excel in the rugged and hazardous conditions typical of mining environments.

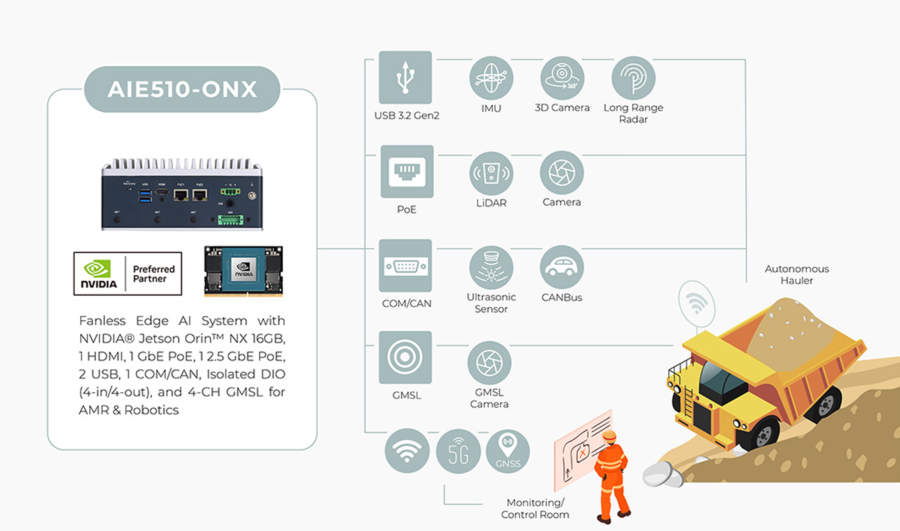

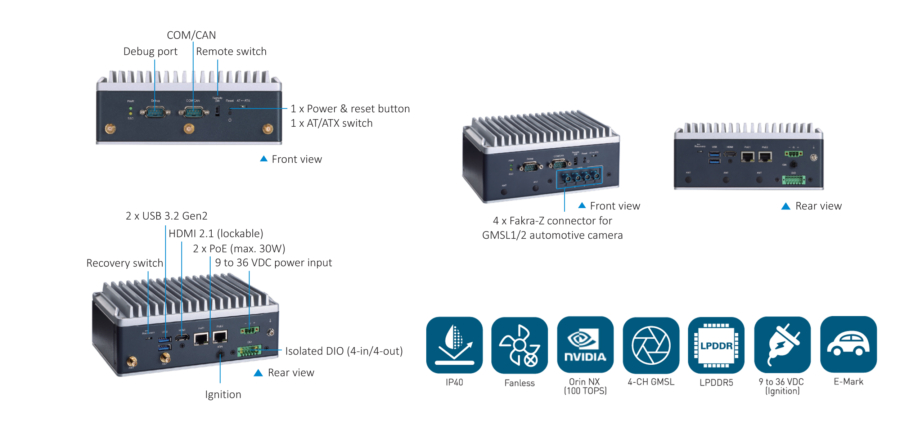

AIE510-ONX: High-Performance Edge-AI Platform for AMR and Robotics in Harsh Environments

The AIE510-ONX is powered by the NVIDIA® Jetson Orin™ NX, delivering up to 100 TOPS of AI computing power. This high-performance platform is capable of analysing vast amounts of images and supports the NVIDIA Isaac™ Robot Operating System (ROS) SDK for AI-enabled robot development.

Key Features of AIE510-ONX and Their Benefits:

- AI Accelerator (NVIDIA® Jetson Orin™ NX 16GB, 100 TOPS):

- Benefit: Delivers exceptional AI performance, enabling rapid and efficient data processing, essential for real-time decision-making and advanced robotic functionalities.

- CPU (8-core NVIDIA Arm® Cortex A78AE v8.2 64-bit CPU with 2MB L2 + 4MB L3 cache):

- Benefit: Provides robust processing power for handling complex computational tasks, ensuring smooth and efficient operation of autonomous systems.

- GPU (1024-core NVIDIA Ampere GPU with 32 Tensor Cores):

- Benefit: Enhances machine learning and AI capabilities, allowing for high-speed image processing and advanced visual analytics.

- System Memory (16GB 128-bit LPDDR5 onboard):

- Benefit: Supports high-speed data access and processing, crucial for handling large datasets and ensuring seamless performance.

- COM (1 x DB9 for COM & CAN):

- Benefit: Ensures reliable communication with other devices and systems within the mining operation, facilitating integrated and coordinated functionalities.

- USB (2 x USB 3.2 Gen2):

- Benefit: Provides high-speed connectivity for external devices, supporting faster data transfer and peripheral integration.

- Ethernet/PoE (1 x 10/100/1000 Mbps PoE via Orin™ NX and 1 x 10/100/1000/2500 Mbps PoE via Intel® I226-IT):

- Benefit: Ensures robust and flexible network connectivity, essential for real-time data transmission and remote control capabilities.

- Display (1 x HDMI 2.1 supporting 4K2K resolution):

- Benefit: Offers high-resolution display output, enabling detailed monitoring and visualisation of mining operations.

- GMSL (4 x Fakra-Z connectors for GMSL1/2 automotive cameras on the AIE510-ONX-GMSL model):

- Benefit: Supports high-speed, low-latency data transmission from multiple cameras, enhancing situational awareness and precision in navigation.

- Digital I/O (1 x Isolated DIO, 4-in/4-out):

- Benefit: Facilitates secure and reliable input/output operations, crucial for interfacing with various sensors and actuators in the mining environment.

- Storage (1 x M.2 Key M 2280 with PCIe x4 NVMe SSD slot):

- Benefit: Provides high-speed, high-capacity storage solutions, essential for managing extensive data generated by autonomous operations.

- Expansion (Slots for Wi-Fi 6E, LTE, and 5G connectivity):

- Benefit: Enables wireless communication, ensuring flexibility and connectivity in challenging mining environments.

- Other Features:

- SMA-type antenna connectors, debug port, various switches, and buttons for operation

- Benefit: Enhance operational control and connectivity, ensuring robust and reliable performance.

- 9 to 36VDC power input, ignition connector, grounding screw

- Benefit: Supports flexible and reliable power supply options, ensuring continuous operation in diverse conditions.

- SMA-type antenna connectors, debug port, various switches, and buttons for operation

- Construction (Aluminium extrusion and heavy-duty steel, IP40 rated):

- Benefit: Ensures durability and protection against environmental factors, crucial for rugged mining applications.

- Operating Temperature (-25°C to +60°C):

- Benefit: Guarantees reliable performance across a wide range of temperatures, essential for harsh mining environments.

- Dimensions (180 x 124 x 71.7 mm for the 16GB model and 180 x 124 x 80.7 mm for the GMSL model):

- Benefit: Compact size for easy integration into various systems and vehicles.

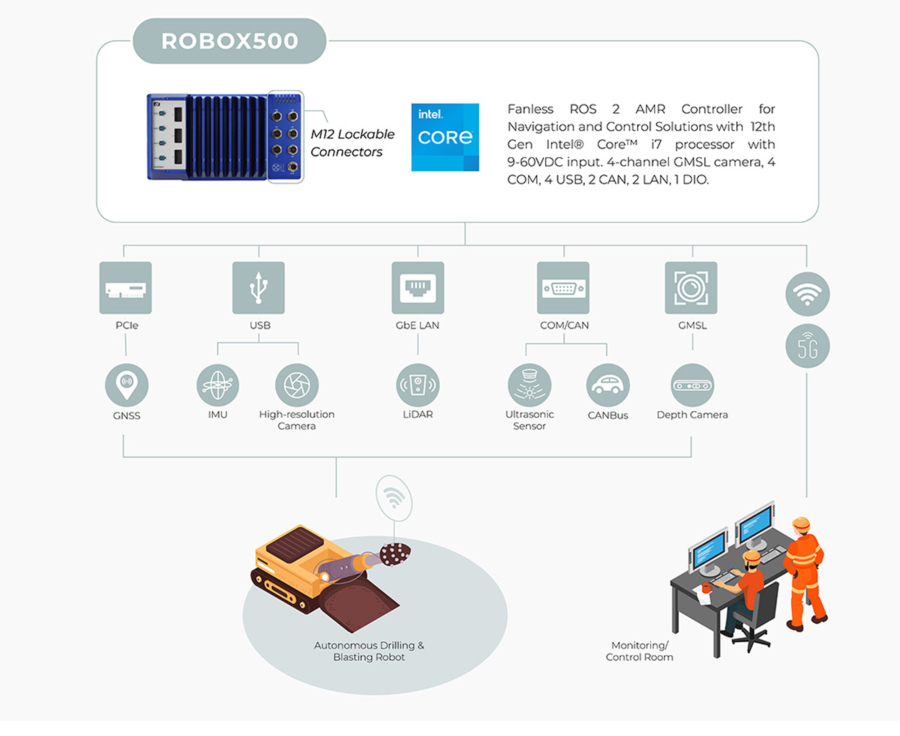

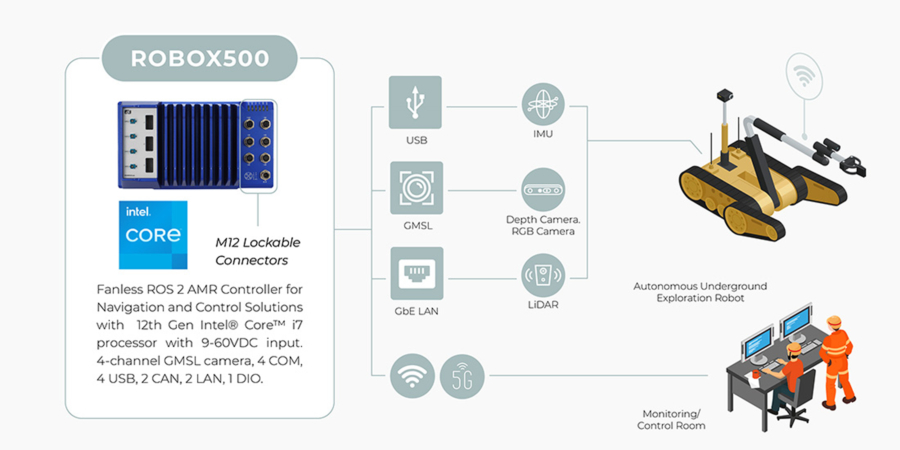

ROBOX500: AMR Controller for Heavy-Duty Industries with M12 Connectors and GMSL Interface

The ROBOX500 is designed for heavy-duty industrial applications, powered by 13th/12th Gen Intel® Core™ i7 processors. This controller features a low-power consumption design with a TDP of 15W/28W and supports a scalable AI module with an M.2 Key M 2242 slot, making it ideal for autonomous robots.

The ROBOX500, powered by the Intel RealSense™ D457 Depth Camera, is the first Automated Mobile Robot (AMR) controller built on the X86 architecture featuring a GMSL interface. This groundbreaking solution from Axiomtek and Intel is designed to handle complex image transmission, making it ideal for the most demanding industrial environments and challenging tasks. With the ROBOX500, companies can achieve superior performance and reliability in heavy-duty applications, setting a new standard in AMR technology.

The clients robots were to be deployed for drilling and blasting, and exploration.

Key Features of ROBOX500 and Their Benefits:

- Processor (13th/12th Gen Intel® Core™ i7):

- Benefit: High processing power for complex data handling and real-time decision-making in autonomous operations.

- GMSL Interface (4-ch GMSL for high-speed, low-latency data transmission):

- Benefit: Ensures real-time environmental sensing, enhancing the accuracy and reliability of autonomous navigation.

- Rugged Design (Includes M12 lockable connectors, 5G anti-vibration capability, and support for extreme operating temperatures):

- Benefit: Durability and robustness for harsh industrial conditions, ensuring consistent performance

- AI Module Support:

- Chipset:

- Intel® QM580:

- Benefit: Reliable chipset ensuring smooth and efficient system operations.

- Intel® QM580:

- System Memory:

- 2 x DDR5 SO-DIMM, up to 64GB:

- Benefit: Sufficient memory capacity for handling large datasets and ensuring smooth multitasking.

- 2 x DDR5 SO-DIMM, up to 64GB:

- Storage:

- 2 x 2.5” SATA drive bays, 1 x M.2 Key M 2280 slot for NVMe:

- Benefit: High-capacity and high-speed storage options for extensive data management.

- 2 x 2.5” SATA drive bays, 1 x M.2 Key M 2280 slot for NVMe:

- USB:

- 4 x USB 3.2 Gen2, 2 x USB 2.0:

- Benefit: Multiple high-speed USB ports for connecting peripheral devices and ensuring fast data transfer.

- 4 x USB 3.2 Gen2, 2 x USB 2.0:

- Ethernet:

- 2 x 10/100/1000 Mbps LAN ports:

- Benefit: Reliable and fast network connectivity for seamless communication and data transfer.

- 2 x 10/100/1000 Mbps LAN ports:

- Display:

- 2 x HDMI 2.0, 1 x DP 1.4:

- Benefit: High-resolution display outputs for detailed monitoring and visualisation.

- 2 x HDMI 2.0, 1 x DP 1.4:

- Expansion Slots:

- 1 x PCIe x16, 2 x PCIe x4:

- Benefit: Flexible expansion options for integrating additional components and enhancing system capabilities.

- 1 x PCIe x16, 2 x PCIe x4:

- Audio:

- 1 x Line-out, 1 x Mic-in:

- Benefit: Audio connectivity for various multimedia applications.

- 1 x Line-out, 1 x Mic-in:

- Power Supply:

- Input: 9 to 60 VDC:

- Benefit: Flexible power input range ensuring reliable operation in different conditions.

- Input: 9 to 60 VDC:

- Operating Temperature:

- -40°C to +70°C:

- Benefit: Wide temperature range support ensuring consistent performance in extreme environments.

- -40°C to +70°C:

- Construction:

- Aluminium extrusion and heavy-duty steel, IP40:

- Benefit: Robust and durable construction for harsh industrial environments.

- Aluminium extrusion and heavy-duty steel, IP40:

- Mounting Options:

- Wall mount, DIN-rail kit, VESA mount kit:

- Benefit: Versatile mounting options for various installation requirements.

- Wall mount, DIN-rail kit, VESA mount kit:

- Certifications:

- CE, FCC Class A, UKCA, E-Mark:

- Benefit: Compliance with international standards ensuring safety and reliability.

- CE, FCC Class A, UKCA, E-Mark:

Key Benefits

- Increased Efficiency: Both AIE510-ONX and ROBOX500 enhance operational efficiency by enabling autonomous operations and real-time data processing.

- Improved Safety: Autonomous robots reduce the need for human presence in hazardous environments, significantly enhancing worker safety.

- Enhanced Productivity: With the ability to operate 24/7, autonomous systems boost productivity and optimise resource utilisation.

- Cost Savings: Reduced labour costs and optimised fuel consumption lead to significant cost savings.

- Environmental Sustainability: Advanced technologies support more sustainable mining practices, reducing the environmental impact of mining operations.

Summary

The integration of advanced technologies like IoT, AI, and autonomous robotics is revolutionising the mining industry, marking the transition to Mining 4.0. The case of the mining company highlights how Axiomtek’s AIE510-ONX and ROBOX500 controllers play a pivotal role in this transformation. These high-performance edge AI platforms are designed to excel in the demanding conditions of mining environments, offering robust, efficient, and reliable solutions for autonomous operations.

The comprehensive features and benefits of the AIE510-ONX and ROBOX500 demonstrate their suitability for various mining applications, from ore and waste transportation to drilling, blasting, and exploration. As the mining industry continues to evolve, the adoption of such advanced technologies will be crucial in addressing the challenges of safety, efficiency, and sustainability, ensuring the industry remains at the forefront of technological innovation.