In this article:

- The Client

- The Demands of The Application

- The Solution

- Cincoze Fanless Embedded Computer - Cooling Techniques

- Main Heating Element - CPU

- Rich I/O and Modular Expansion

- Rugged and Certified

- Specifications

- Cincoze DS-1302 Technical Drawings and Diagrams

The Client

In today’s industries, X-ray inspection systems are indispensable for ensuring product quality, safety, and compliance. With the integration of embedded computers, these systems have witnessed significant advancements, offering improved efficiency, enhanced capabilities, and precise results.

Benefits they bring to this critical inspection process:

- Advanced Image Processing and Analysis for Accurate Results: Embedded computers revolutionise image processing and analysis capabilities in X-ray inspection systems. With their processing power, these computers employ sophisticated algorithms to enhance image quality, detect defects, and identify anomalies with exceptional accuracy. Leveraging embedded computing technology enables X-ray inspection systems to produce clearer, more detailed images, empowering operators to make informed decisions swiftly and confidently.

- Rapid Inspection and High Throughput for Efficient Operations: Embedded computers enable X-ray inspection systems to achieve rapid inspection and high throughput rates. With their processing capabilities, embedded computers quickly analyse X-ray images, facilitating faster defect detection and foreign object identification. This not only improves productivity but also ensures efficient handling of large volumes of items within time-sensitive production environments. Integrating embedded computers reduces inspection time, streamlines workflows, and increases operational efficiency.

- Real-time Monitoring and Quality Control for Enhanced Production: Embedded computers facilitate real-time monitoring and quality control in X-ray inspection systems. Continuously analysing X-ray images as items pass through the inspection process, these computers identify potential defects or deviations from predefined quality standards. Immediate feedback empowers operators to take corrective actions promptly, minimizing waste, reducing rework, and ensuring consistent product quality. Real-time monitoring enables proactive decision-making, preventing issues from escalating and maintaining optimal production efficiency.

- Integration with Automation and Industry 4.0 for Streamlined Processes: Embedded computers seamlessly integrate X-ray inspection systems with automation processes and Industry 4.0 initiatives. With their computing capabilities, X-ray systems communicate with other equipment, such as robotic arms or conveyors, automating the handling and sorting of inspected items. This integration enhances efficiency, reduces human intervention, and enables a more streamlined and synchronized production process. Additionally, embedded computers facilitate connectivity and data exchange, allowing X-ray inspection systems to contribute to data-driven insights and smart manufacturing strategies.

- Enhanced Operator Experience and Ease of Use for Optimal Performance: Embedded computers enhance the operator experience and simplify the use of X-ray inspection systems. Intuitive graphical user interfaces (GUIs) and touchscreen displays enable operators to navigate through system controls, adjust settings, and interpret inspection results effortlessly. The responsive and user-friendly interface, powered by embedded computing technology, reduces the learning curve, enabling operators to utilize the system's full potential effectively. This leads to increased productivity, reduced operator fatigue, and improved overall user satisfaction. The integration of embedded computers in X-ray inspection systems has significantly enhanced the capabilities and efficiency of this critical inspection process. Advanced image processing, rapid inspection, real-time monitoring, and seamless integration with automation and Industry 4.0 initiatives are among the many benefits that embedded computers bring to X-ray inspection systems. X-ray inspection systems are one of the most efficient non-destructive inspection technologies in the industrial field today, performing quality control and testing by scanning objects with X-rays to detect internal defects or foreign objects. Compared with traditional detection methods, X-ray inspection is non-destructive, high-precision, and highly efficient. It is widely used in automotive, aerospace, electronics, food, medical equipment, and other industrial fields, playing a key role in optimizing quality control and testing, and effectively helping manufacturers to bolster production efficiency. According to a market report released by ReportLinker, the global X-ray inspection systems market is estimated to exceed USD 1.1 billion by 2030.

A well-known European X-ray inspection equipment manufacturer needed an embedded computer to integrate into its industrial-grade automatic X-ray inspection system. The system is suitable for a variety of material detection, such as metal casting, steel components, aluminium alloys, plastics, ceramics, and more.

Combined with the deep learning software developed by the equipment manufacturer, it can detect, locate, and classify defects, making it a great tool for automated quality management.

The Demands of The Application

High-Performance Processor

The embedded computer in the X-ray machine vision system required powerful computing abilities to serve as its processing core. It was required to efficiently handle numerous images from the frame grabber card and apply deep learning techniques for analysis. Moreover, it was to seamlessly connect with peripheral devices and networks, ensuring speedy and adaptable processing capabilities.

PCIe Expansion

For machine vision in an inspection system, the embedded computer needed PCIe slots to enable the installation of a frame grabber card, enabling high-resolution image processing and analysis.

Multiple High-speed LAN and High Expandability

To accommodate diverse job requirements, the embedded computer was required to be able to handle multiple high-speed network interfaces for efficient data transmission with network storage servers and the cloud. Additionally, it was to have expandability to connect with handling axes or peripherals while meeting interconnection requirements for edge computing devices.

The Solution

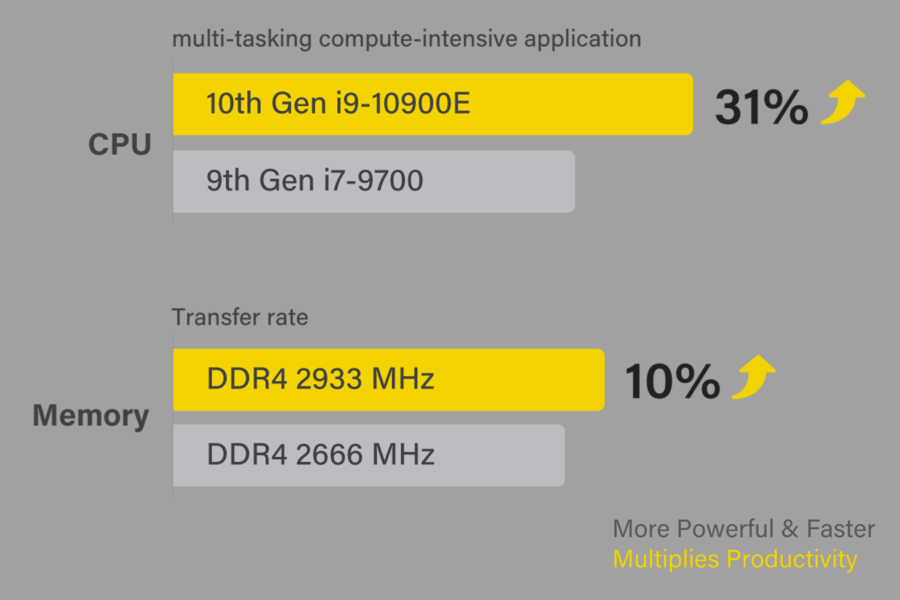

The client opted for the rugged embedded computer, Cincoze DS-1302, as the inspection system’s core platform. This highly expandable device offers high-performance capabilities, accommodating an Intel® Xeon® or Core™ processor with up to 10 cores and 80W TDP, and up to 64GB of DDR4 memory. Its impressive computing power makes it ideal for factory automation applications, including machine vision and AOI defect detection.

The DS-1302 employs Cincoze’s specialised heat dissipation structure for passive cooling. Additionally, it can support external fans to enhance heat dissipation and maintain stability during demanding workloads.

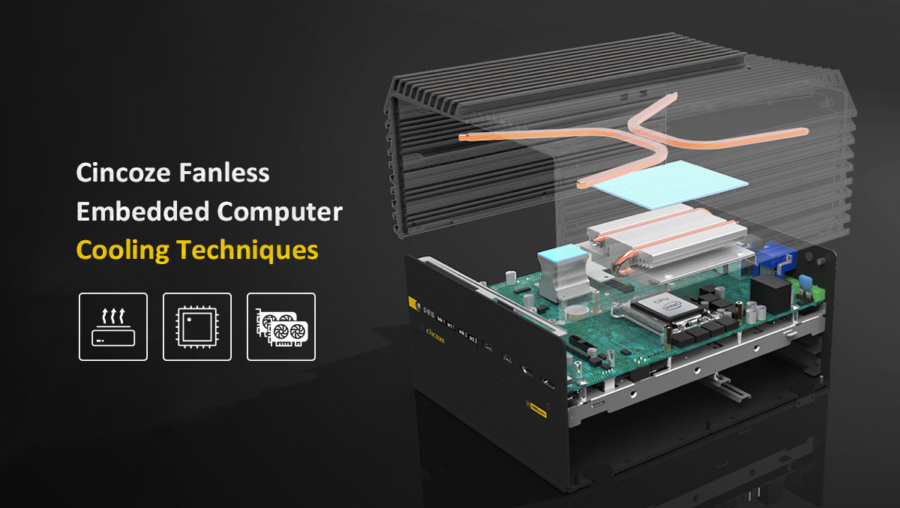

Cincoze Fanless Embedded Computer - Cooling Techniques

Effective heat dissipation is a critical element for stable operation.

Cincoze offers durable and dependable fanless embedded computers designed for various applications. Computers such as the DS-1302, prioritize stability and feature a unique heat dissipation structure, allowing for wide temperature operation (-40°C to 70°C) that surpasses industry standards.

Excessive temperatures can have detrimental effects on the lifespan of computer parts, leading to performance degradation, CPU throttling, or even system shutdown. Fortunately, Cincoze employs unique techniques to strike the perfect balance between performance and heat dissipation. Before delving into Cincoze’s cooling solution, it’s crucial to understand that the motherboard harbours various heat sources, including the CPU, chipset, GPU, LAN controller, Choke, MOSFET, and others.

In general, two cooling methods prevail: active cooling, utilising fans to efficiently expel hot air from heat-generating components, and passive cooling, harnessing specific metals’ conductive properties to transfer heat to the system’s outer shell.

The DS-1302 is purpose-built to withstand harsh conditions in various installation environments, such as extreme temperatures, high humidity, and dusty surroundings, like outdoor settings or production lines.

This design enhances robustness and eliminates the risk of dust accumulation, ensuring seamless operation even in demanding environments.

Cincoze’s DS-1302 features a meticulously calculated and precision-designed cooling solution, crafted by their R&D unit’s skilled thermal design engineer during the early stages of product development. The goal is to achieve the perfect equilibrium between cooling and performance by designing the system to efficiently dissipate heat from the CPU and GPU, surpassing the rate at which it is generated.

Main Heating Element - CPU

The CPU, as the primary heat source in a computer, is crucial for processing operations, interpreting instructions, and controlling computer functions. While heat is less of an issue under lighter workloads, multitasking and high-speed CPU performance result in significant heat generation. Ensure efficient heat management with our solutions for optimal CPU performance and reliable operation.

Heatsink

Cincoze’s carefully designed heatsinks efficiently transfer heat from the CPU to the system chassis. Leveraging the unique properties of aluminium and copper, their heatsinks ensure fast heat dissipation and conduction, respectively. By combining copper tubes and aluminium blocks, the heatsink design maximizes upward heat transfer from the CPU while preventing heat build-up within the system chassis.#

Thermal Pad

Enhance heat transfer efficiency with Cincoze’s thermal pad technology. By utilizing a low thermal resistance silicone thermal pad boasting an impressive thermal conductivity of up to 12.5W/mK, air gaps are minimized, ensuring optimal heat transfer. Benefit from reduced contact thermal resistance and unlock superior performance.

Cooling Copper Pipe

Optimize heat dissipation with our innovative design featuring copper heat pipes housed within an extruded aluminium shell. These heat pipes exhibit excellent thermal conductivity, efficiently transferring heat to the outer surface of the aluminium cover. Specifically engineered for high-wattage CPU and GPU models, our design ensures superior heat management.

Aluminium Extrusion Case

Optimise heat dissipation in your embedded computer with Cincoze’s aluminium shells renowned for their excellent thermal properties. Our dedicated thermal design engineers strategically incorporate fins of different heights and shapes on the external surface, maximizing the overall surface area to enhance heat dissipation efficiency. Unlike other market offerings, Cincoze’s unique unibody chassis not only ensures superior heat dissipation but also provides exceptional strength.

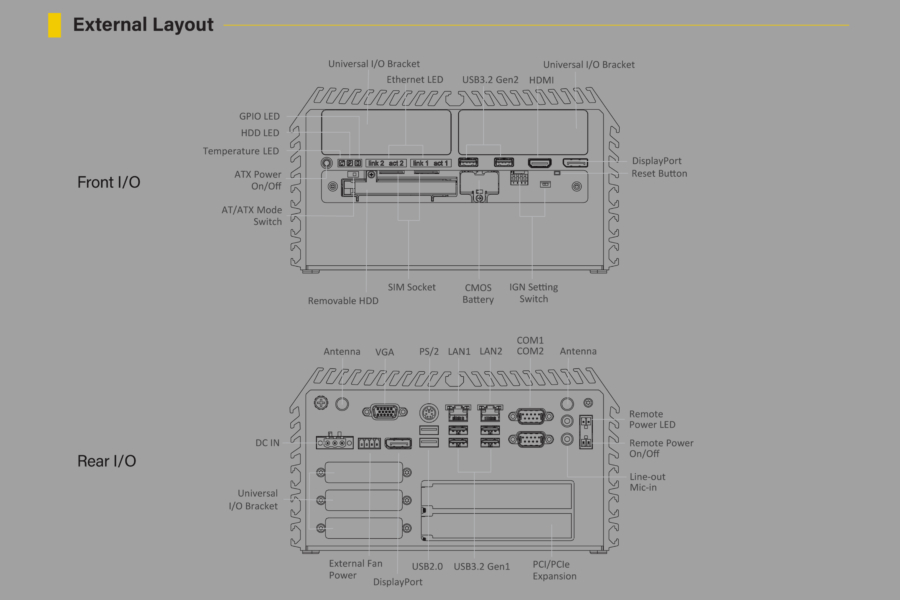

Rich I/O and Modular Expansion

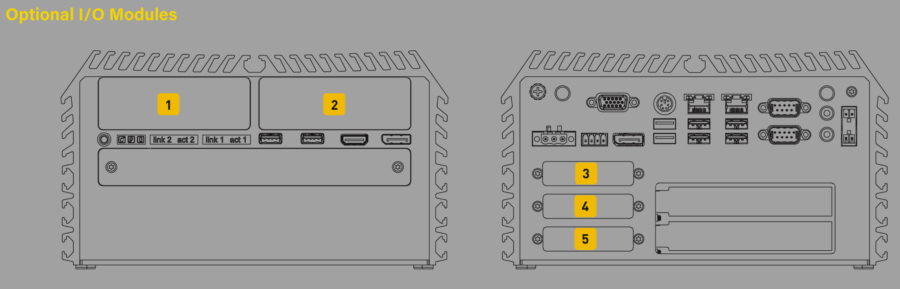

In addition to the rich selection of native I/O ports, including 2x GbE LAN, 6x USB 3.2, and 2x USB 2.0, a selection of expansion options are available for various industrial applications. Cincoze’s exclusive CMI and MEC modules allow for an additional 12x GbE LAN, 2x 10 GbE LAN, 32x DIO, 8x M12, 4x COM, or 4x USB 3.2, while the CFM modules support IGN and PoE. Furthermore, two PCI/PCIe slots can be connected to various high-speed I/Os, GPU cards, video capture cards, motion cards, and more.

To keep expansion cards firmly secured, Cincoze’s patented two-stage Adjustable Card Retainer (patent no. I773359) fits expansion cards of almost any size.

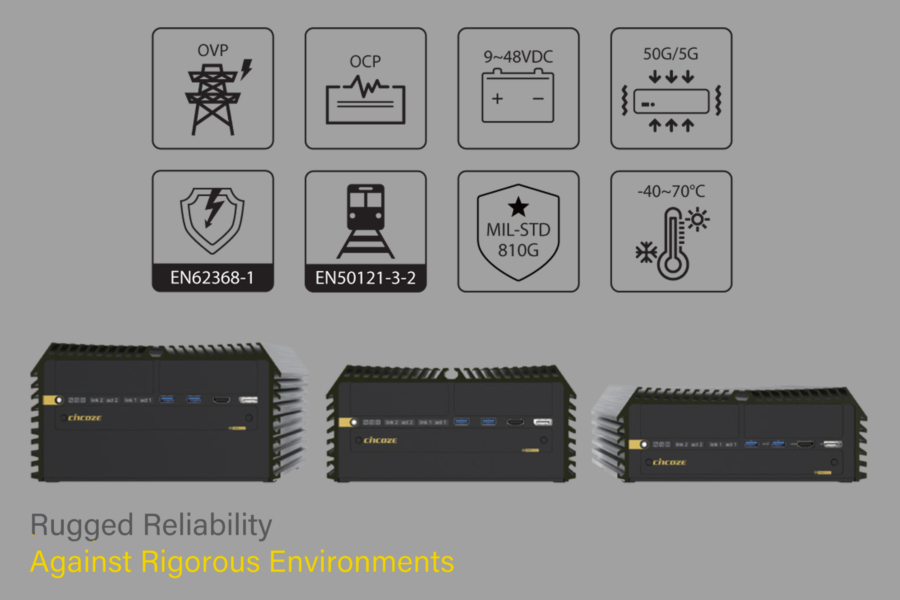

Rugged and Certified

The DS-1302 offers uninterrupted operation in demanding industrial environments and is equipped with a range of industrial-grade designs and protections. Compliant with industrial specifications, the DS-1302 offers a wide operating temperature range (-40°C to 70°C), wide-range DC power input (9 – 48 VDC), and robust overvoltage, overcurrent, and ESD protection, ensuring long-term stability. Rigorously tested to meet stringent standards, including MIL-STD-810G military standard and EN50155 (EN 50121-3-2 only) for rolling stock environments, the DS-1302 guarantees reliability and stability.

Specifications

- 10-core 10th-gen Intel Xeon and Core i9/i7/i5/i3 CPU (max 80 W TDP)

- 2x GbE LAN and optional 2x 10GbE LAN

- 2x 2.5″ SATA storage, 3x mSATA sockets, 1x M.2 key M for NVMe SSD

- 2x PCI/PCIe expansion slots

- 3x full-size Mini PCIe sockets, 2x SIM card slots

- Optional CMI modules for I/O expansion

- Optional CFM modules for ignition sensing & PoE

- Wide operating temperature -40°C to 70°C

- MIL-STD-810G military standard and EN50155 (EN 50121-3-2 only)

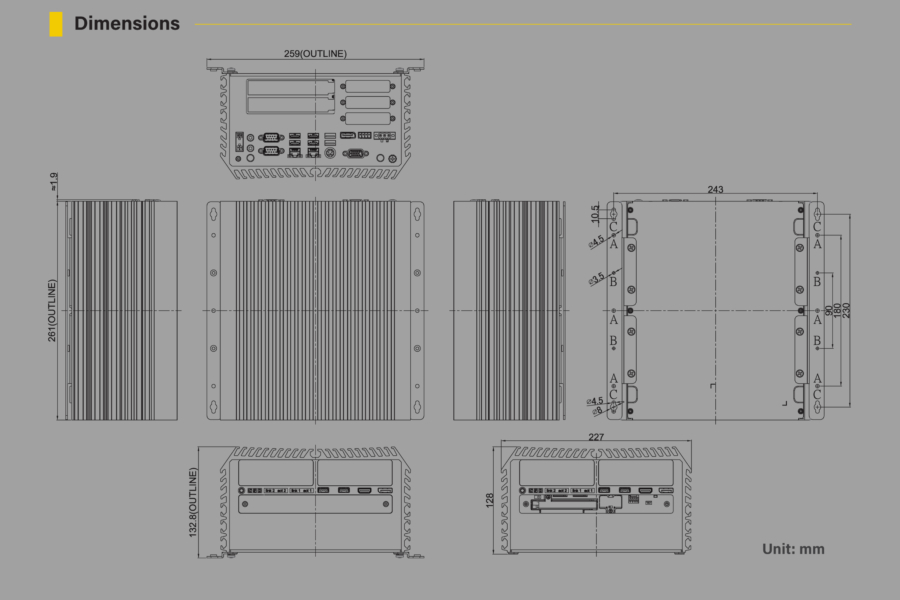

Cincoze DS-1302 Technical Drawings and Diagrams