In this article:

- What is an Open Frame Panel PC?

- Key Benefits of Open Frame Panel PCs being used for Engine Monitoring

- Practical Applications on Cruise Ships

- The Demands of The Application

- The Solution

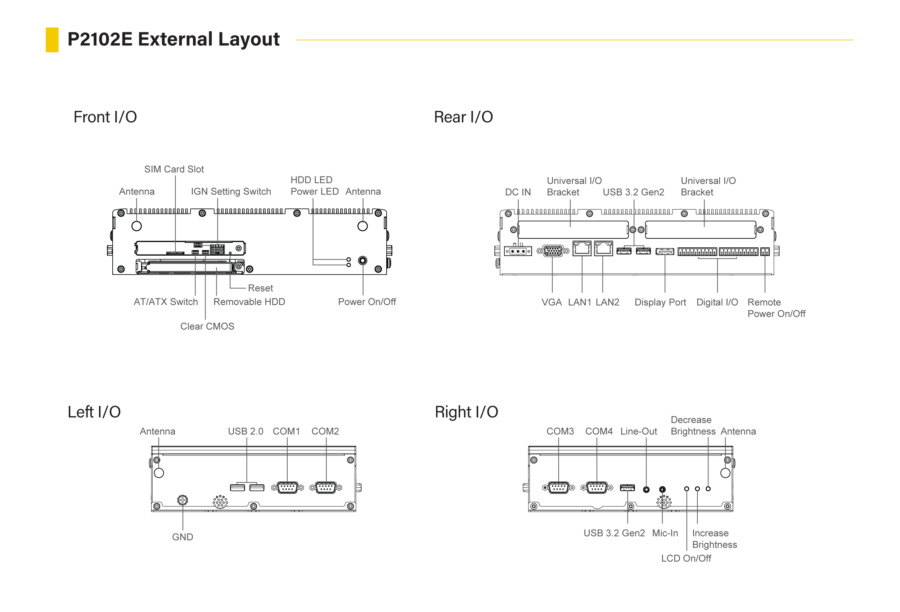

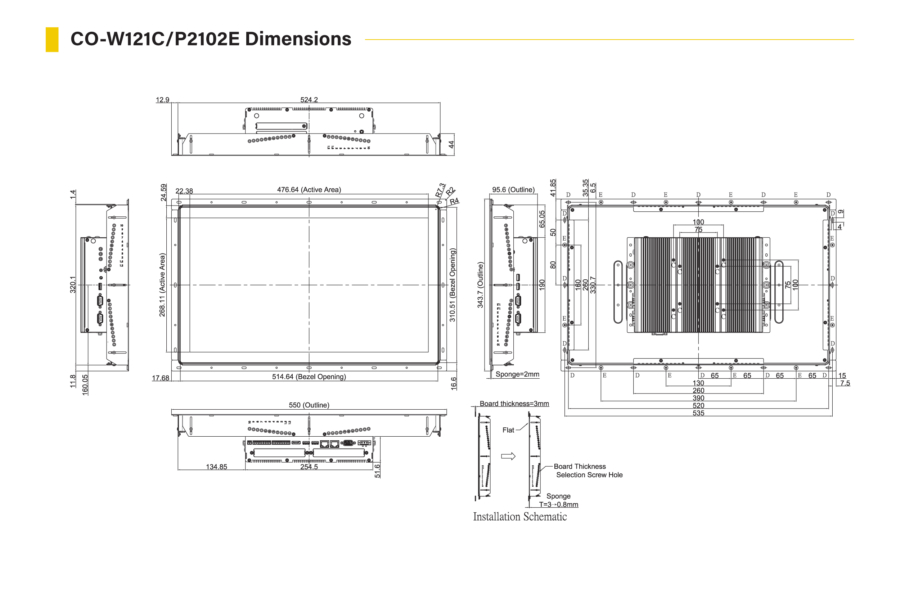

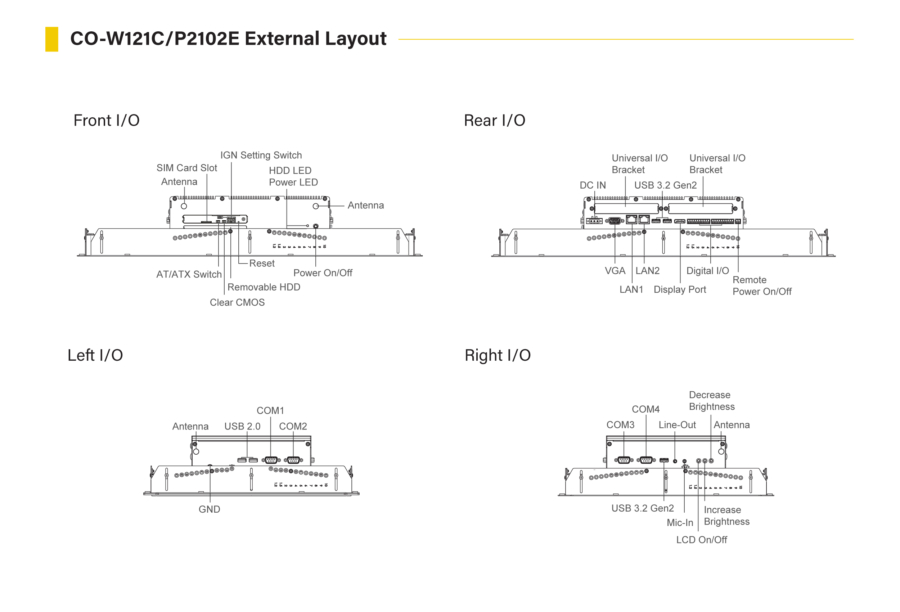

- Technical Drawings

According to statistics from the globally recognised data platform Statista, the number of cruise passengers is projected to reach 32.53 million by 2027. As cruise ships play a crucial role in passenger transportation, onboard systems like engine monitoring, power management, and safety systems are essential for ensuring efficient and safe operations.

As the maritime industry continuously evolves, cruise ships are becoming more sophisticated, integrating advanced technologies to improve safety, efficiency, and overall passenger experience.

The client, a renowned Central European systems integrator, required an ‘Open Frame Panel PC’, a versatile tool that can significantly enhance the monitoring of cruise ship engine status.

What is an Open Frame Panel PC?

An open frame panel PC is a highly adaptable computing solution designed without an enclosure, allowing for easy integration into various industrial applications. These devices typically feature robust construction, high-performance processors, and extensive connectivity options, making them ideal for demanding environments like cruise ships.

Key Benefits of Open Frame Panel PCs being used for Engine Monitoring

- Real-Time Data Monitoring Open frame panel PCs provide real-time data monitoring capabilities, allowing engineers to track engine performance metrics such as temperature, pressure, and fuel consumption continuously. This real-time insight enables prompt identification and resolution of potential issues before they escalate, ensuring the smooth operation of the cruise ship.

- Enhanced Data Visualisation With their high-resolution touchscreens and advanced graphical interfaces, open frame panel PCs offer superior data visualisation. Engineers can easily interpret complex data through intuitive dashboards and visual aids, facilitating better decision-making processes and more effective engine management.

- Remote Monitoring and Control The integration of open frame panel PCs allows for remote monitoring and control of the ship’s engines. Engineers can access the engine status from various locations on the ship or even from a remote office, ensuring constant oversight and quick response times in case of abnormalities.

- Durability and Reliability Engine rooms on cruise ships are harsh environments, characterised by high temperatures, vibrations, and humidity. Open frame panel PCs are built to withstand these conditions, featuring rugged components that ensure reliable performance and longevity, crucial for maintaining uninterrupted monitoring operations.

- Scalability and Flexibility Open frame panel PCs are highly customisable, allowing for scalability and integration with other shipboard systems. This flexibility ensures that the monitoring system can grow and adapt to meet the evolving needs of the cruise ship’s operations, accommodating future technological advancements.

Practical Applications on Cruise Ships

- Comprehensive Engine Diagnostics Open frame panel PCs enable comprehensive diagnostics of the cruise ship’s engines. By integrating with sensors and other diagnostic tools, they provide detailed analysis and reports on engine health, helping to pre-emptively address wear and tear, thus avoiding costly repairs and downtime.

- Efficient Energy Management Monitoring fuel consumption and engine efficiency in real-time helps in optimising energy use on the cruise ship. Open frame panel PCs can be programmed to alert engineers about inefficient engine performance, prompting timely adjustments that can lead to significant fuel savings and reduced environmental impact.

- Integration with Centralised Management Systems These panel PCs can be integrated with centralised management systems, offering a unified platform to oversee various aspects of the cruise ship’s operations. This holistic approach ensures that engine monitoring is not isolated but part of a broader strategy to enhance the vessel’s overall performance and safety.

- Proactive Maintenance Scheduling By continuously monitoring engine performance and identifying trends, open frame panel PCs facilitate proactive maintenance scheduling. This approach ensures that maintenance tasks are performed at optimal times, minimising disruption to the ship’s itinerary and extending the lifespan of the engines.

The Demands of The Application

Open Frame Design for High-Performance Engine Monitoring

For effective cruise ship engine monitoring, customers require a high-performance industrial panel PC. This panel PC receives real-time data from sensors, visualises it, and allows operators to quickly assess engine status for adjustments and predictive maintenance. To ensure seamless integration with other control room equipment, an open frame industrial panel PC was chosen, aligning perfectly with existing systems and meeting all operational requirements.

Essential COM Ports for Comprehensive Engine Monitoring

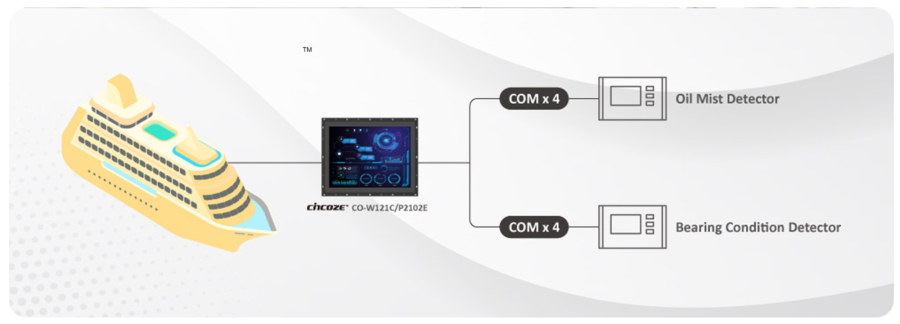

For effective engine oil mist and bearing monitoring on cruise ships, a computer with at least six COM ports is essential. This capability allows for the connection to multiple sensors, ensuring real-time data acquisition and comprehensive monitoring of critical engine components.

Durability in Harsh Maritime Environments

Cruise ships face significant temperature and humidity variations, along with harsh weather conditions, impacts from waves, vibrations, and electromagnetic interference. To prevent monitoring interruptions and avoid challenging maintenance situations at sea, a rugged and highly reliable industrial panel PC is essential. This ensures continuous operation and durability in the demanding maritime environment.

The Solution

The client selected Cincoze’s open frame panel PC (CO-W121C/P2102E) to monitor the cruise ship engines effectively. This advanced panel PC connects to multiple sensors, collecting data for real-time analysis and enabling preventive maintenance. By monitoring for potential issues like engine overheating, shutdowns, and component damage due to bearing wear or excessive oil mist, the Cincoze CO-W121C/P2102E enhances engine safety and reduces maintenance costs, ensuring optimal performance for cruise ships.

The Cincoze open frame panel PCs (CO-100/P series) cater to diverse performance needs with options including Intel® Core™ U, Pentium®, and Atom® processors. These PCs deliver high-performance data processing and graphics capabilities, essential for effective cruise ship engine monitoring. A standout feature is their easy installation, thanks to the exclusive adjustable mounting bracket (Patent No.: D224544, D224545, I802427), which offers thickness adjustment settings and two locking methods (panel or boss type), ensuring seamless integration into ship control cabinets.

Available in a range of sizes from 19” to 21” with 5:4 and 16:9 display ratios and multi-point capacitive touch, the Cincoze open frame panel PCs (CO-100/P series) provide versatility and convenience, making them an ideal choice for enhancing cruise ship engine monitoring systems.

Flexible Expansion for Comprehensive Cruise Ship Engine Monitoring

Effective monitoring of mist and bearing in cruise ship engines requires connectivity to multiple sensors. The Cincoze CO-W121C/P2102E is equipped with 4 built-in COM ports, and can expand to 8 COM ports using Cincoze’s unique MEC module, meeting all sensor connection requirements. Additionally, two Mini-PCIe slots and one PCI/PCIe x4 slot provide further expansion options for data acquisition cards or additional I/O, ensuring a comprehensive and adaptable engine monitoring system.

Easy Maintenance and Upgrades for Cruise Ship Systems

Cruise ships often encounter challenges with equipment upgrades and maintenance. The Cincoze CO-W121C/P2102E, utilising Cincoze’s CDS patented technology (Patent No. M482908), simplifies these processes. This technology allows for easy screen replacements, system upgrades, and troubleshooting. By enabling quick component swaps, it minimises downtime and ensures that the system remains operational with minimal disruption.

Rugged and Reliable for Harsh Maritime Environments

The CO-W121C/P2102E is built with industrial-grade protections, making it ideal for maritime use. Its fanless design, wide operating temperature range (0°C to 60°C), wide voltage support (9 to 48 VDC), and IP65 waterproof and dustproof front panel ensure long-term reliability in harsh conditions. This rugged construction guarantees dependable performance for cruise ship engine monitoring, even in the most challenging maritime environments.

Technical Drawings