In this article:

- The Client

- Streamlined Machine Control and Monitoring:

- Simplified Changeovers and Configuration:

- Enhanced Fault Detection and Troubleshooting:

- Operator Training and Support:

- Data Collection and Analysis:

- The Demands of The Application

- The Solution

- System Configurations of the GOT818W-511-C-DC

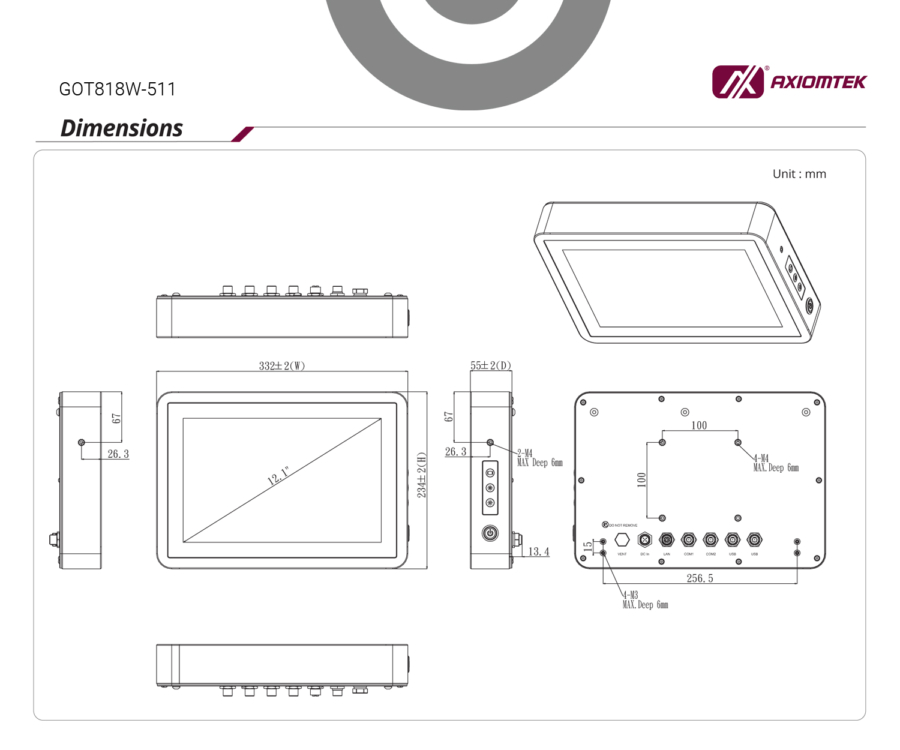

- Technical Drawings - GOT818W-511-C-DC

The Client

In today’s rapidly evolving industrial landscape, automation has revolutionized various sectors, including packaging and manufacturing. Automated packaging machines play a pivotal role in transforming production processes, driving efficiency, minimising errors, and boosting productivity. However, it is the integration of a Human-Machine Interface (HMI) that takes these advantages to unprecedented heights.

The customer sought to improve operator productivity and achieve faster manufacturing throughput in their automated packaging machine.

Human-Machine Interfaces (HMIs) often serve as the cornerstone of seamless communication and control between operators and automated packaging machines. By bridging the gap between humans and machines, HMIs optimize operational efficiency and deliver a superior user experience:

Streamlined Machine Control and Monitoring:

An HMI (Human-Machine Interface) acts as an intuitive and user-friendly interface, enabling operators to efficiently control and monitor automated packaging machines. With advanced graphical displays, touch screens, and interactive controls, operators can seamlessly manage the entire packaging process with ease.

HMIs provide real-time visibility into critical variables that drive efficient packaging operations. By offering instant access to machine status, production rates, error alerts, and diagnostics, operators are empowered to make informed decisions promptly. This accessibility to vital information allows for the optimization of production schedules, reduction of downtime, and increased throughput.

Simplified Changeovers and Configuration:

Automated packaging machines often require adjustments to accommodate different products, packaging sizes, or label designs. Traditionally, changeovers involved manual reconfiguration, leading to extended downtime and an increased potential for errors. However, with the integration of HMIs, changeovers become a seamless and efficient process.

HMIs empower operators to streamline changeovers by providing access to pre-configured recipes or utilising intuitive graphical interfaces. This enables operators to quickly set up the machine for a new product without the need for extensive manual adjustments. As a result, valuable time is saved, and the potential for errors associated with manual configuration is significantly reduced.

By simplifying the changeover process, HMIs ensure consistency and quality throughout the production process. Operators can rely on pre-configured recipes or intuitive graphical interfaces to ensure accurate and precise settings for each new product. This minimises the risk of errors, maintains consistency in packaging, and upholds the desired quality standards.

Enhanced Fault Detection and Troubleshooting:

In any manufacturing environment, unforeseen faults or breakdowns can have a significant impact on productivity. However, HMIs play a vital role in swiftly detecting and diagnosing these issues, ensuring minimal disruption to operations.

HMIs utilise intelligent monitoring systems to identify anomalies, irregularities, or deviations in machine performance. By constantly analysing real-time data, HMIs can promptly detect potential faults and alert operators to take immediate action. These real-time alerts and detailed diagnostic information empower operators to troubleshoot problems promptly, reducing downtime and minimising production losses.

The intuitive nature of HMIs further faci litates quick identification of the root causes behind these faults. Operators can navigate through the HMI interface to access comprehensive data and diagnostic insights, enabling them to pinpoint the source of the problem efficiently. This quick identification leads to faster resolution and the implementation of preventive measures to avoid similar issues in the future.

Operator Training and Support:

The integration of HMIs in automated packaging machines plays a crucial role in simplifying operator training and reducing the learning curve. Intuitive graphical interfaces, complemented by step-by-step instructions, enable new operators to quickly understand machine functionalities, operations, and troubleshooting techniques.

HMIs provide a range of training resources to facilitate operator learning. Comprehensive user manuals, video tutorials, and contextual help systems can be incorporated into the HMI interface, empowering operators with the knowledge required to effectively operate the machinery. These resources offer accessible and comprehensive guidance, allowing operators to become proficient in a shorter period.

By minimising reliance on specialised technical skills, HMIs enhance workforce flexibility. Operators can quickly adapt to new machines and processes, reducing the need for extensive training or hiring specialised personnel. This flexibility not only saves time and resources but also reduces the risk of errors caused by human factors.

Data Collection and Analysis:

In the era of Industry 4.0 and data-driven decision-making, HMIs serve as a gateway to gather and analyse valuable production data in automated packaging machines. By seamlessly integrating with underlying automation systems, HMIs collect data on machine performance, production rates, downtime, and quality metrics.

This data can be visualised in real-time, providing operators and manufacturers with instant insights into production processes. Additionally, the data can be exported for further analysis, enabling manufacturers to delve deeper into performance metrics and identify areas for improvement.

By leveraging this information, manufacturers can identify bottlenecks, optimise processes, and implement continuous improvement initiatives. Real-time data visualisation allows for prompt decision-making, enabling operators and management to take proactive steps in improving efficiency and productivity.

Furthermore, HMIs enable the integration of advanced analytics and machine learning algorithms. By analysing the collected data, these technologies can facilitate predictive maintenance, identifying potential issues before they occur. This proactive approach minimises downtime and optimises maintenance schedules, resulting in cost savings and improved operational efficiency.

The integration of Human-Machine Interface technology with automated packaging machines has revolutionised the manufacturing industry. HMIs provide a bridge between operators and machines, enabling streamlined control, real-time monitoring, simplified changeovers, and efficient troubleshooting. By empowering operators with intuitive interfaces, HMIs maximize productivity, reduce errors, and optimise overall efficiency. As technology continues to advance, the potential of HMIs in automated packaging machines will only grow, driving further progress and revolutionising the industry.

The Demands of The Application

When the customer sought to improve operator productivity and achieve faster manufacturing throughput in their automated packaging machine, they turned to a customised, industrial-grade touch panel PC solution. This tailored solution ensures optimal performance and durability to meet the specific needs of the industrial environment.

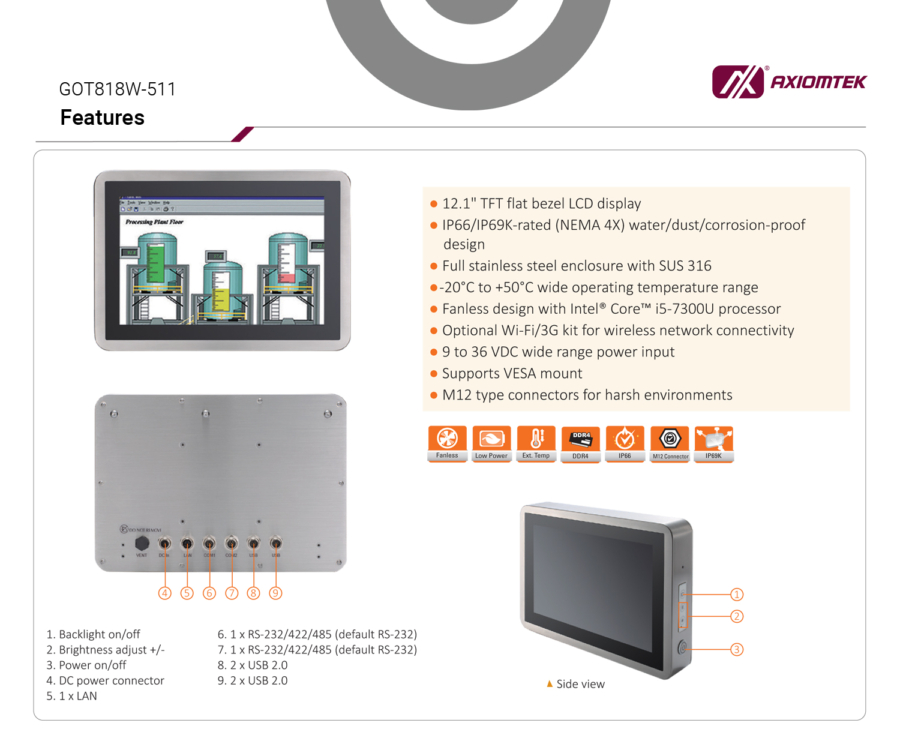

The key requirement for the touch panel PC was a robust IP55 stainless steel enclosure. This ensures protection against dust, water, and other environmental factors, safeguarding the PC from potential damage. The stainless-steel construction also provides durability, making it suitable for the rugged conditions commonly found in manufacturing settings.

In addition to the robust enclosure, the touch panel PC is equipped with M12-type connectors for the power connector and LAN port. These connectors are specifically designed to withstand vibrations generated by the machine, ensuring stable and reliable connectivity even in demanding operational conditions.

Main Requirements

18.5-inch multi-touch projected capacitive screen

IP55 and 316 stainless steel enclosure

Fanless and flat panel design

M12 power connector

M12 GbE LAN

Supports wireless connectivity

Supports VESA mount

The rugged touch panel PC enables real-time control and monitoring of the automated production.

The Solution

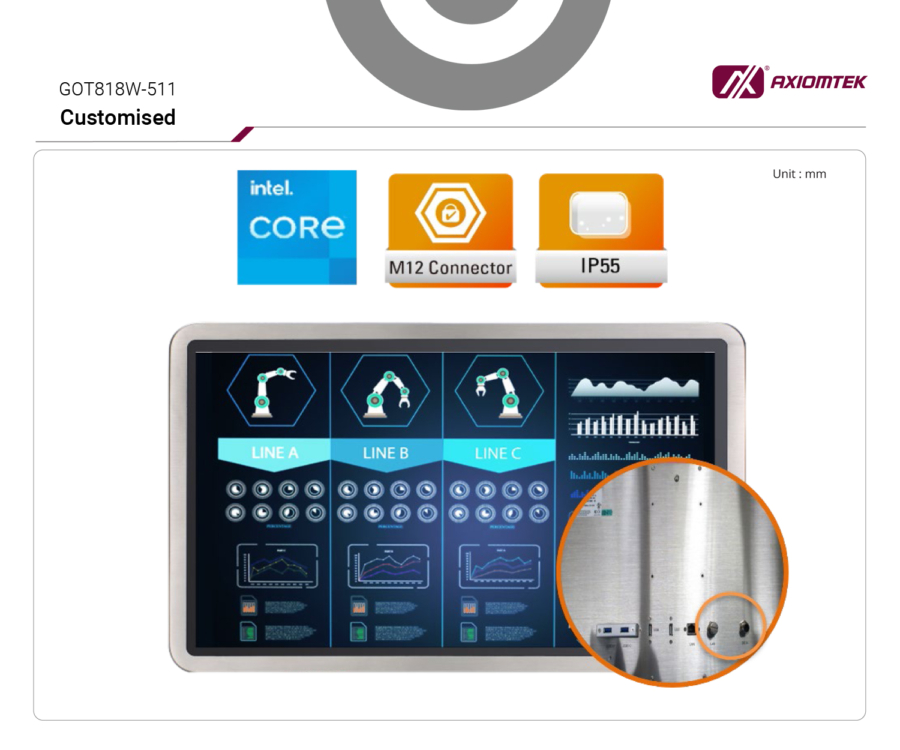

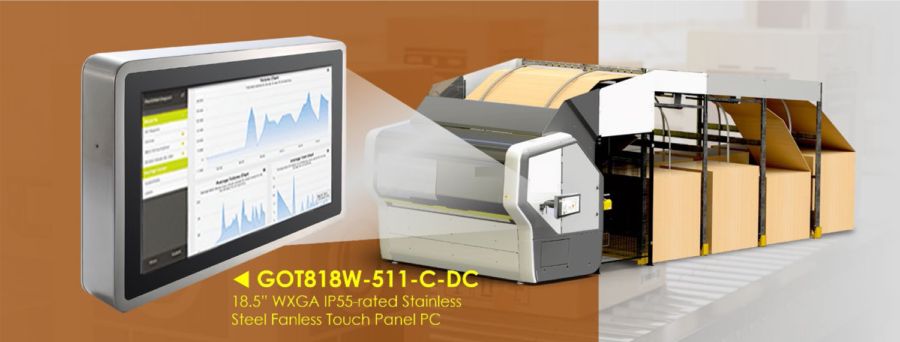

Axiomtek’s GOT818W-511-C-DC was proposed with a customised 18.5-inch stainless steel fanless touch panel PC, the GOT818W-511-C-DC, featuring the high-performance Intel® Core™ i5 processor. In addition to the IP55 rating, the power connector and one of the GbE LAN ports were upgraded to M12 type to increase tightness and vibration resistance. The GOT818W-511-C-DC is designed to withstand harsh industrial environments.

The touch panel PC enables box production of any size.

On-Demand Smart Packaging

The customer has integrated the GOT818W-511-C-DC with its on-demand packaging machinery via a VESA mount for instant viewing in production. With support of the tailor-made software, RSC boxes for any size product can be produced with just a few clicks, and the progress and schedule can be monitored at any time. The durability and extended life cycle of the touch panel PC lower the costs for customers, while optimising the workflow leading to an expected increase in profits.

On-demand packaging solution saves materials to be environment-friendly and the right-sized box minimises the void to reduce damage to the goods during transportation and saves shipping costs as well. As production turns to automation, it also reduces labour costs. Deploying the solution results in increased profits for the end users.

System Configurations of the GOT818W-511-C-DC

High performance Intel® Core™ i5 processor

One 260-pin DDR4-2133 slot, up to 8GB

IP55 and 316 stainless steel enclosure

One 2.5” SATA SSD, up to 64GB

M12 power connector (9 to 36VDC)

M12 GbE LAN

Two RS-232/422/485 ports

Two USB 2.0 ports

Two USB 3.0 ports

Technical Drawings - GOT818W-511-C-DC