In this article:

- Introduction - NISE50 04A-XX Industrial Edge AI Gateway

- Industries and Applications

- Benefits of AI at the Edge

- Key Specifications and How They Benefit Industries

- Summary

Introduction - NISE50 04A-XX Industrial Edge AI Gateway

NEXAIoT (a Nexcom company) recently introduced the NISE-50 04A-XX Series Industrial Edge AI Gateway sytems, an advanced solution designed for high-performance edge computing applications. With the increasing demand for intelligent edge systems, these systems provide industries with a reliable, secure, and scalable platform for real-time data processing and decision-making. Powered by Intel® Atom Amston Lake or Alder Lake processors, the NISE-50 04A-XX Series boasts up to 16GB of DDR5-4800MHz SO-DIMM memory with In-Band Error Correction Code (IBECC), delivering superior multitasking, reliability, and safety. This AI gateway is ideally suited to industries such as factory automation, robotics, industrial IoT (IIoT), and AI-driven analytics.

The NISE-50 04A-XX Series was officially launched at the Embedded World North America event in Austin, Texas, on 8th October 2024. As edge computing continues to grow in importance, this device represents a significant advancement for sectors that rely on processing data closer to the source.

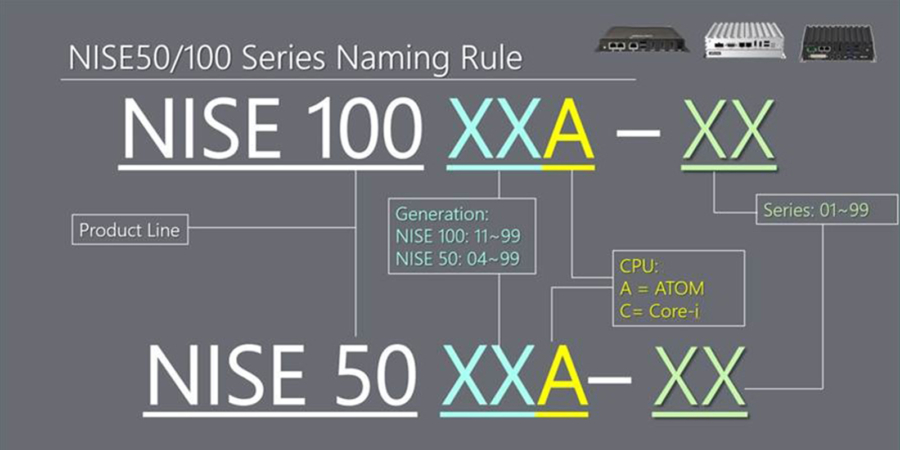

It follows a new series naming rule, with the NISE-50 04A-XX Series including:

Industries and Applications

The NISE-50 04A-XX Series’ versatility makes it an ideal choice for a wide range of industrial applications, each of which benefits from the AI-driven edge computing capabilities it provides. By integrating AI at the edge, industries can make more informed decisions, automate processes, and reduce latency, all of which lead to increased efficiency and lower operational costs.

Below is a deeper dive into the key industries that can benefit from the NISE-50 04A-XX Series, and how it transforms operations within these sectors.

- Factory Automation

Factory automation is essential in modern manufacturing environments, where efficiency and uptime are critical to profitability. By processing data at the edge, the NISE-50 04A-XX Series enhances factory operations with real-time insights, advanced analytics, and AI-based automation.

Suitable Applications for the NISE-50 4A-XX Series in Factory Automation:

- Programmable Logic Controllers (PLC) Gateways: PLCs are crucial for controlling machinery in automated systems. The NISE-50 04A-XX Series, with its low-latency TSN-enabled LAN ports, can serve as a gateway, coordinating communication between factory equipment and the central system. This results in smoother, more precise control over factory operations.

- Predictive Maintenance Systems: Factory equipment generates vast amounts of operational data. By processing this data locally, the NISE-50 04A-XX Series can predict equipment failure or necessary maintenance before a breakdown occurs, reducing costly downtime and improving overall efficiency.

- Real-Time Quality Control: AI-driven visual inspection systems are increasingly being used in manufacturing to identify defects and ensure product quality. The NISE-50 04A-XX Series’ AI capabilities enable it to process high-resolution video streams at the edge, reducing latency and improving the accuracy of quality control checks.

- Energy Management: The NISE-50 04A-XX Series can be used to monitor and optimise energy consumption across manufacturing equipment. By gathering and analysing data from energy meters, the gateway enables real-time decisions to reduce power consumption during low-demand periods.

How the NISE 54 Can Be the Solution:

- Edge AI Processing: AI capabilities like Intel Deep Learning Boost allow the NISE-50 04A-XX Series to process predictive maintenance algorithms and run real-time machine learning models for quality control at the edge.

- Low Latency for Real-Time Control: The Time-Sensitive Networking (TSN) capability ensures low-latency, synchronised communication between machines and PLCs, enabling more precise and efficient factory operations.

- Enhanced Connectivity: With support for 2.5GbE LAN ports and M.2 slots for 5G or Wi-Fi, the NISE-50 04A-XX Series provides reliable and high-speed communication for connected devices in the factory.

- Industrial IoT (IIoT)

The Industrial Internet of Things (IIoT) connects machines, sensors, and devices in an industrial setting to enable real-time monitoring, control, and analytics. The NISE-50 04A-XX Series acts as a bridge between connected devices and cloud or centralised data centres, processing and analysing data locally to reduce latency and bandwidth usage.

Suitable Applications for the NISE-50 o4A-XX Series in Industrial IoT:

- Smart Manufacturing: In IIoT environments, smart sensors and actuators collect data from machines and production lines. The NISE-50 04A-XX Series can process this data locally to provide real-time insights, which improves operational efficiency and production management.

- Remote Monitoring of Industrial Equipment: The NISE-50 04A-XX Series can collect and process data from industrial equipment located in remote or hazardous environments. With its extended operating temperature range (-40°C to 60°C), the NISE-50 04A-XX Series is reliable in challenging environments such as power plants or offshore platforms.

- Environmental Monitoring: Factories and industrial sites often need to monitor environmental factors such as temperature, humidity, and air quality. The NISE-50 04A-XX Series can aggregate data from environmental sensors and process it locally to ensure compliance with safety regulations.

- Supply Chain Management: IIoT systems in supply chain management require real-time tracking of assets. The NISE-50 04A-XX Series 5G connectivity options allow it to manage data from connected devices across the supply chain, providing valuable insights for inventory management and logistics.

How the NISE50 04A-XX Series Can Be the Solution:

- Local Data Processing: The NISE-50 04A-XX Series processes IIoT data locally, reducing the need to transfer large amounts of data to the cloud, lowering costs, and improving response times.

- Scalable Connectivity: With multiple M.2 slots supporting Wi-Fi, 5G, and LTE, the NISE-50 04A-XX Series offers versatile connectivity options, allowing it to communicate with a wide range of IIoT devices.

- Robust Design: Its rugged design allows the NISE-50 04A-XX Series to function in extreme environments, making it ideal for industrial applications in remote or harsh locations.

- Robotics and Autonomous Systems

Robotic systems are revolutionising industries such as manufacturing, logistics, and healthcare. These systems rely on fast, accurate decision-making capabilities, often requiring edge computing to reduce latency and ensure real-time processing of sensor data.

Suitable Applications for the NISE-50 04A-XX Series in Robotics and Autonomous Systems:

- AI-Powered Vision Systems: Robots often need to “see” and understand their environment to perform tasks like object recognition, sorting, and assembly. The NISE-50 04A-XX Series integrated Intel UHD Graphics and support for AI inference makes it an ideal choice for processing visual data locally.

- Pathfinding and Navigation for Autonomous Vehicles: In warehouses, logistics centres, and industrial sites, autonomous vehicles need to navigate complex environments. The NISE-50 04A-XX Series AI capabilities and real-time data processing can be used to run pathfinding algorithms and process LIDAR or camera data.

- Collaborative Robots (Cobots): Cobots work alongside humans to perform tasks such as assembly, packaging, and quality inspection. The NISE-50 04A-XX Series’ edge AI processing enables real-time decision-making and fast response times, ensuring that co-bots can operate safely and efficiently.

- Industrial Robotics Control: In automated production lines, the NISE-50 04A-XX Series can serve as the brain of robotic systems, processing commands and adjusting operations in real-time to ensure optimal performance.

How the NISE-50 04A-XX Series can be the solution:

- AI Inference at the Edge: The NISE-50 04A-XX Series Intel DL Boost and AVX2 support with INT8 capabilities allow it to handle advanced AI tasks such as object detection and autonomous decision-making, which are critical for robotic systems.

- Fast, Real-Time Processing: Robotics require low-latency data processing to ensure timely decision-making. The NISE-50 04A-XX Series support for TSN enables real-time communication between robots and control systems.

- Edge AI for Reduced Latency: By processing AI algorithms locally, the NISE-50 04A-XX Series eliminates the latency associated with cloud-based AI, allowing robots to respond quickly and autonomously.

- AI-Powered Analytics

AI-powered analytics is transforming industries by providing real-time insights into operations, helping businesses optimise performance, improve quality, and reduce downtime. The NISE-50 04A-XX Series allows companies to run AI models at the edge, enabling data-driven decisions without relying on centralised cloud resources.

Suitable Applications for the NISE-50 04A-XX Series in AI-Powered Analytics:

- Predictive Maintenance: In industries such as manufacturing, oil and gas, and transportation, predictive maintenance is essential for keeping equipment running efficiently. The NISE-50 04A-XX Series can analyse equipment data in real-time, identifying patterns that indicate an impending failure and triggering maintenance before costly downtime occurs.

- Real-Time Operational Optimisation: In manufacturing plants, data from machines and production lines can be analysed in real-time to identify bottlenecks and inefficiencies. It can process this data locally and provide recommendations for optimisation, improving production throughput and reducing waste.

- Supply Chain Optimisation: AI-powered analytics can be used to optimise supply chains by analysing data from various points along the supply chain in real-time. The NISE-50 04A-XX Series enables businesses to process data at distribution centres, warehouses, and other edge locations, allowing for better decision-making around inventory management, transportation, and delivery times.

- Quality Control in Production: Real-time AI analytics powered by the NISE-50 04A-XX Series can detect defects on production lines, ensuring that only high-quality products are sent to customers. This improves customer satisfaction and reduces the cost of rework and recalls.

How the NISE-50 4A-XX Series can be the solution:

- AI Processing Power: The NISE-50 04A-XX Series’ AI capabilities enable it to run machine learning and deep learning algorithms locally, allowing businesses to gain insights in real-time without relying on cloud infrastructure.

- Real-Time Data Analysis: By processing data at the edge, the NISE-50 04A-XX Series reduces latency and enables real-time analytics, allowing businesses to make faster, more informed decisions.

- Seamless Integration with Existing Systems: The NISE-50 04A-XX Series can be easily integrated into existing industrial networks, enabling businesses to leverage their current data sources while adding powerful AI-driven analytics at the edge.

- Energy Sector

The energy sector is increasingly turning to edge computing to monitor and optimise assets such as wind turbines, solar panels, and oil rigs in real-time. The NISE-50 04A-XX Series ability to operate in harsh environments and process large volumes of data makes it an ideal solution for this industry.

Suitable Applications for the NISE-50 04A-XX Series in the Energy Sector:

- Remote Monitoring of Energy Assets: The NISE-50 04A-XX Series can be deployed in remote locations to monitor the performance of energy assets such as wind farms or solar panels. With its wide operating temperature range and reliable connectivity options (such as 5G and LTE), it ensures seamless communication with central systems.

- Predictive Maintenance for Energy Equipment: By processing sensor data from energy assets locally, the NISE-50 04A-XX Series can predict when maintenance is required, preventing costly failures and reducing downtime.

- Energy Grid Optimisation: The NISE-50 04A-XX Series can be used to monitor energy consumption and grid performance, analysing data in real-time to improve grid stability and reduce energy waste.

- Oil and Gas Monitoring: In the oil and gas industry, the NISE-50 04A-XX Series can be used to monitor and control equipment in harsh environments, providing real-time data on operations and ensuring that systems are running efficiently and safely.

How the NISE-50 04A-XX Series can be the solution:

- Rugged Design for Harsh Environments: The NISE-50 04A-XX Series is built to withstand extreme temperatures and environmental conditions, making it ideal for energy applications in remote or challenging locations.

- Edge Processing: With powerful AI and real-time processing capabilities, the NISE-50 04A-XX Series can analyse sensor data on-site, reducing the need for cloud processing and enabling faster response times.

- Reliable Connectivity: Whether through 5G, LTE, or Wi-Fi, the NISE-50 04A-XX Series offers multiple connectivity options, ensuring that energy assets remain connected to centralised monitoring systems.

Benefits of AI at the Edge

By integrating AI at the edge, the NISE-50 04A-XX Series offers numerous benefits across various industries, including:

- Reduced Latency: By processing data at the edge, closer to where it is generated, the NISE-50 04A-XX Series eliminates the need to send data to the cloud for analysis, reducing latency and enabling faster decision-making.

- Improved Efficiency: AI-powered edge computing allows businesses to automate processes, optimise workflows, and reduce operational costs.

- Enhanced Security: Edge computing reduces the amount of sensitive data sent to the cloud, lowering the risk of data breaches and improving overall cybersecurity.

- Scalability: The NISE-50 04A-XX Series can be easily integrated into existing industrial systems, allowing businesses to scale their AI and edge computing capabilities as needed.

Key Specifications and How They Benefit Industries

The NISE-50 04A-XX Series’ impressive technical specifications make it a powerful tool for edge AI applications. Here’s a closer look at its key features and the benefits they bring to industrial operations:

- Intel® Atom Processors with AI Acceleration

The NISE-50 04A-XX Series is powered by Intel® Atom Amston Lake or Alder Lake processors, which offer a balance of performance and energy efficiency. With integrated Intel UHD Graphics, Intel DL Boost, and Intel AVX2 with INT8 support, the NISE-50 04A-XX Series can handle complex AI inference tasks such as image recognition, machine learning, and deep learning.

- AI Inference: The combination of Intel UHD Graphics and DL Boost allows the NISE-50 04A-XX Series to perform real-time AI inference, making it ideal for applications such as vision systems, robotics, and autonomous decision-making.

- Energy Efficiency: The Atom processors’ low power consumption makes the NISE-50 04A-XX Series suitable for edge applications that require 24/7 operation without excessive energy usage.

- 16GB DDR5 Memory with In-Band ECC

The NISE-50 04A-XX Series supports up to 16GB of DDR5-4800MHz SO-DIMM memory with In-Band Error Correction Code (IBECC). This ensures high-performance multitasking while maintaining system reliability and data integrity.

- Enhanced Reliability: IBECC ensures that the system can detect and correct memory errors in real-time, making the NISE-50 04A-XX Series suitable for mission-critical applications where reliability is paramount.

- Improved Multitasking: The high-speed DDR5 memory allows the NISE-50 04A-XX Series to handle multiple tasks simultaneously, ensuring smooth operation even in complex industrial environments.

- Comprehensive M.2 Storage and Connectivity

The NISE-50 04A-XX Series’ versatile M.2 interface supports a range of storage and connectivity options, including M.2 2242/2280 Key B for SATA storage, M.2 2230 Key E for Wi-Fi/Bluetooth, and M.2 2242/3042/3052 Key B for 5G/LTE/SATA. This allows businesses to customise their edge computing setup based on their specific needs.

- Flexible Storage Options: The M.2 storage interface allows businesses to choose from a range of storage options, ensuring that the NISE-50 04A-XX Series can handle the large volumes of data generated by industrial devices.

- Enhanced Connectivity: With support for 5G/LTE, Wi-Fi, and Bluetooth, the NISE-50 04A-XX Series ensures seamless communication between devices, making it ideal for IIoT and other connected systems.

- USB-C Power Delivery and Display Support

The NISE-50 04A-A03 variant supports USB-C Power Delivery (PD) of up to 80W, enabling efficient power transfer and the ability to power multiple peripherals with a single cable. Additionally, USB-C with PD can support high-resolution displays, making the NISE-50 04A-XX Series suitable for applications that require interactive user interfaces or digital signage.

- Efficient Power Management: USB-C PD simplifies power management by allowing businesses to power multiple devices with a single cable, reducing clutter and improving efficiency.

- Display Support: With USB-C Alt Mode, the NISE-50 04A-XX Series can power and control high-resolution displays, making it ideal for digital signage and other interactive applications in industrial environments.

- Robust Security and Reliability

The NISE-50 04A-XX Series is equipped with TPM 2.0 (Trusted Platform Module) to provide advanced security features such as secure boot and data encryption. Additionally, the device can operate in temperatures ranging from -40°C to 60°C, making it suitable for use in harsh industrial environments.

- Data Security: TPM 2.0 ensures that sensitive data is protected, making the NISE-50 04A-XX Series ideal for industries where security is a top priority.

- Extended Temperature Range: The NISE-50 04A-XX Series ability to operate in extreme temperatures ensures reliable performance in environments such as outdoor industrial sites, power plants, and logistics hubs.

- Time-Sensitive Networking and Real-Time Communication

With three Intel 2.5GbE LAN ports that support Time Coordinated Computing (TCC) and Time-Sensitive Networking (TSN), the NISE-50 04A-XX Series is designed for real-time applications that require precise timing and low-latency communication. This is crucial for industries such as factory automation, robotics, and autonomous systems.

- Real-Time Performance: TCC and TSN enable the NISE-50 04A-XX Series to handle time-critical workloads, ensuring that machines and devices communicate synchronously with minimal latency.

- Industrial Automation: The low-latency communication provided by TSN makes the NISE-50 04A-XX Series ideal for controlling PLC gateways, robotics, and other automation systems.

Summary

The NISE-50 04A-XX Industrial Edge AI Gateway from NEXCOM is a versatile and powerful solution that brings AI and edge computing to a range of industries. Whether in factory automation, robotics, IIoT, or AI-powered analytics, the NISE-50 04A-XX Series offers real-time data processing, enhanced connectivity, and secure, reliable operation. With its advanced AI capabilities, flexible storage and connectivity options, and robust security features, the NISE-50 04A-XX Series is poised to drive innovation and transform industrial operations.

As industries continue to embrace the benefits of AI at the edge, the NISE-50 04A-XX Series provides a future-proof solution that helps businesses stay competitive in an increasingly data-driven world. Whether improving operational efficiency, enabling predictive maintenance, or enhancing cybersecurity, the NISE-50 04A-XX Series offers the features and performance needed to meet the demands of modern industrial applications.